Why graft?

Grafting involves joining a fruit-producing shoot (called the ‘scion’) of a desirable cultivar onto the disease-resistant rootstock of another cultivar. For example, let’s say you normally grow the cultivar ‘QualiT-47’ for fruit production, but that cultivar is susceptible to a soilborne disease problem in your fields, then you could graft the top part of a ‘QualiT-47’ seedling onto the root-portion of a more disease-resistant cultivar. In the case of tomato rootstocks, the majority of the cultivars are interspecific hybrids between cultivated tomato (Solanum lycopersicum) and wild tomato species (most commonly Solanum habrochaites, or less often S. peruvianum or S. cheesmaniae). Solanum habrochaites is known from other published research to be tolerant of salinity, drought, cold temperatures, and resistant to many soilborne diseases and many of these benefits have been demonstrated to be conferred to the grafted plant when an interspecific hybrid rootstock is used.

Most of us are familiar with grafting as a standard practice for California fruit and nut trees and grapevines, but it has experienced only limited commercial adoption among annual crops in California thus far. Grafted tomato transplants are commonly utilized in the commercial greenhouse industry, where tomatoes are produced under protected culture and are generally grown over a much longer production cycle, often a 10-month period. There are greenhouse producers in Southern California, but it is more common in British Columbia, Ontario, Mexico and other US states (Arizona and others). In many countries in Latin America, Europe and Asia, grafted plants represent a large percentage of the tomato industry. For example, in Spain, 50 to 70 million grafted plants are grown annually for greenhouse production systems. There has also been some adoption of grafting by high-tunnel tomato growers in the eastern United States. In Southern California, the nursery Plug Connection is marketing grafted tomatoes to home gardeners, dubbing them as a “Mighty ‘Mato”. This allows a home gardener to grow an heirloom tomato variety, which often has little or no disease resistance, without worrying about rotation or other soilborne disease control measures.

Our goal was to evaluate the potential for grafting standard tomato cultivars onto rootstock cultivars that possess resistance to soilborne diseases and nematodes. Our primary objective was to evaluate the yield performance of grafted plants in replicated trials in commercial fresh market (“mature green”) production fields in the northern San Joaquin Valley. Our team consisted of myself, Scott Stoddard with University of California Cooperative Extension (UCCE) in Merced County, and Michael Grieneisen and Minghua Zhang in the Department of Land, Air and Water Resources at the University of California, Davis. This project produced the first publicly-available research results on grafted tomatoes for California production systems.

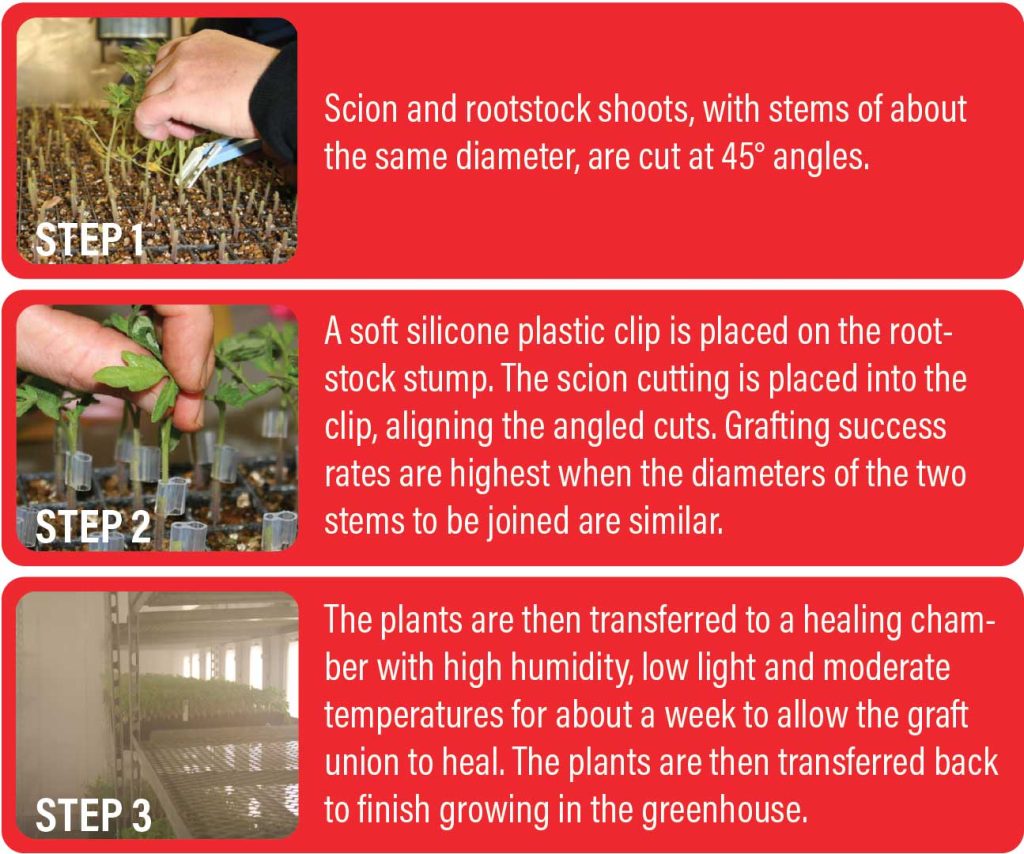

How is it done?

For each tray of grafted tomatoes to be produced, two trays of seed are sown; one tray of the rootstock seed and another tray of the scion seed. At approximately one month after sowing, the young seedlings are grafted. Both seedlings are cut at the hypocotyl, and the scion shoot is spliced onto the rootstock stump. The method we used is a commonly used splice-graft with small, soft, silicone clips to hold the scion and rootstock together during healing. Grafted transplants cost more than non-grafted transplants due to increased seed costs and the labor required to do the grafting. Thus far, grafted tomato plants are only available from a few sources in California, and we won’t know what the cost for grafted tomato transplants will be until they are being produced in larger volumes here. The use of fully- or semi-automated grafting robots is emerging as a way to reduce labor costs and improve the survival rate of grafted plants. This of course requires significant capital investment. About 20 seed companies offer tomato rootstock seeds (see list at http://www.vegetablegrafting.org/tomato-rootstock-table/). However, for a nursery facility or grower considering doing their own grafting, building a healing chamber may be a hurdle. There is research underway by others to look at conducting the one-week healing period inside the greenhouse. For more information on the logistics of grafting on a commercial scale, please see the Vegetable Grafting Manual, the link for which is provided at the end of this article under “More information”.

Field Trials in the Northern San Joaquin Valley

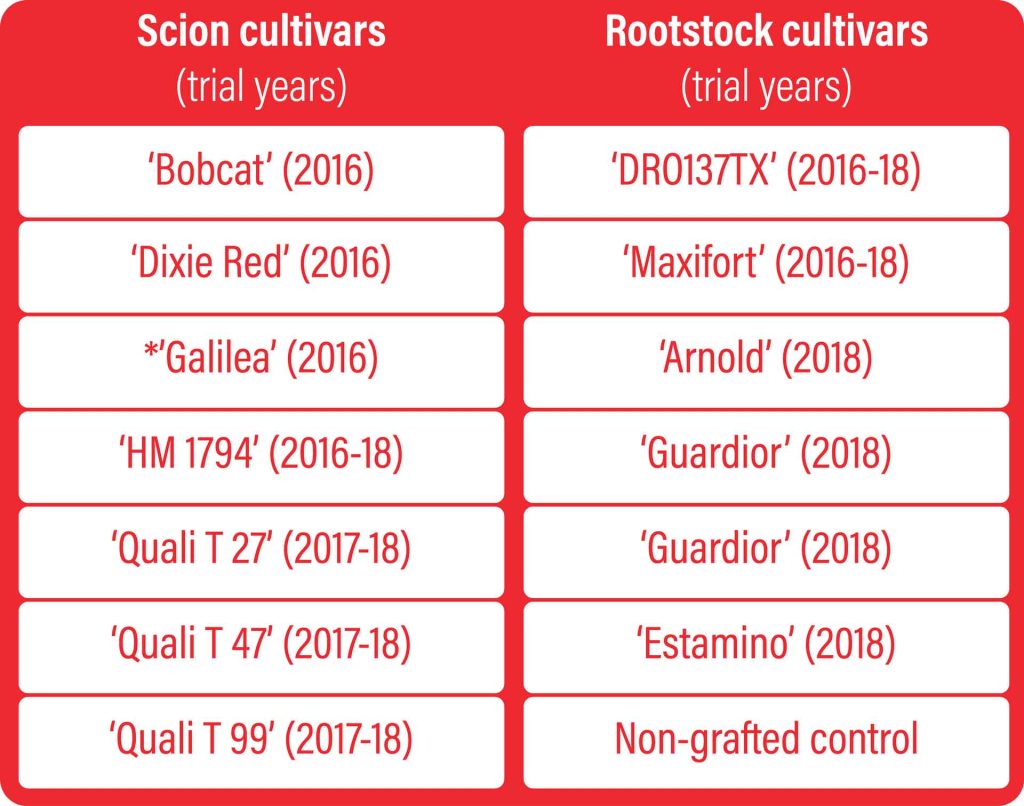

The trials were conducted in commercial production fields at six locations over three years from 2016 to 2018; three locations in San Joaquin County and another three locations in Merced County. The treatments included all combinations of the scions and rootstocks listed in Table 2.

The plots were laid out in a randomized complete-block design with four replicate blocks, each block measuring approximately 80 by 40 feet. The cooperating growers managed the experimental plots similarly to the rest of their field with respect to pest control, fertilization, irrigation, and other management practices. Plants were mechanically transplanted into prepared beds at a 4- to 5-inch depth per normal practice; the graft union ended up well below the soil surface. In staked or trellised production systems in other regions, the graft union is typically kept above ground to realize the full benefit of the rootstock pathogen resistance. With graft union buried below the soil surface, soilborne pathogens may attack the scion crown tissues or adventitious roots arising from the scion. Due to the lack of significant pathogen pressure in our fields, we believe this was not an issue for these trials.

In our trials, grafted plants were more vigorous and had better foliage cover of fruit at harvest than non-grafted plants of the same cultivar. We also measured NDVI (Normalized Difference Vegetation Index, a measure of the “greenness” or how much of the bed is covered with actively photosynthesizing foliage) and it was also slightly higher in grafted plots. Averaged across all six trials, marketable yield increased only 12 percent when grafting with ‘Maxifort’ or ‘DRO138TX’ as the rootstock, although the results were better in some individual trials. At the San Joaquin County sites, yields of non-grafted vines were similar to the statewide average yield and grafting increased yield significantly (25 to 40 percent depending on the year). Some scion-rootstock combinations were as much as 68 percent higher than the non-grafted plants of the same scion (e.g. ‘QualiT-27’ on ‘Maxifort’ at the San Joaquin site in 2018). At the Merced sites, yields of non-grafted vines were well above-average and grafting was much less beneficial. Many published field trials indicate that the yield advantages of grafted plants are greatest under sub-optimal growing conditions. Field sites with heavy soilborne disease pressure, or abiotic stresses may be the best candidates to see improvements with grafting.

Fruit Size and Quality

Many published studies have found that grafted plants produce a higher percentage of fruit in larger size classes than those produced by the non-grafted scion varieties. Averaged over all our trials, the differences in fruit size distribution between grafted and non-grafted were fairly small. In some trials, however, plants on vigorous rootstocks did have larger fruit. Some published studies provide measures of fruit quality, such as dissolved sugars, pH, total dissolved solids, vitamin C, lycopene, or even “taste-test” data. Those studies indicate that the quality of fruit from grafted plants seems to be slightly inferior to fruit from the non-grafted plants, though still commercially acceptable. Our field trials focused on yields, and we did not measure any fruit quality data. However, we did not notice any fruit defect problems in grafted vines. Also, in 2018 we did cut open both red and mature green fruit at harvest to make sure that there were no problems inside the fruit.

Variability From Trial to Trial or Field to Field

A study in Florida with determinant type cultivars has shown yield increases of 25 to 42 percent using certain rootstocks, but year-to-year variability also increased as compared to non-grafted plants. This variation underscores the importance of considering variable outcomes to determine the feasibility of grafted tomatoes here. Some fields will likely benefit more from grafting than others, and this may not always be predictable in advance.

Economics

Costs of field establishment are increased significantly with grafting. Materials costs for transplanting (seed plus nursery costs) alone might be $2,000 per acre or higher or more than with conventional transplants. However, we don’t yet really know what the costs might be if this were adopted commercially in California, so our plant costs are based on small volume sales prices. If we assume a cost of $0.40 per grafted plant, then a yield increase of 19 percent at a market price of $6.55 per 25-pound box would pay for the increased plant cost.

On-going and Future Work

Other research projects looking at grafting tomatoes are being conducted in California. A United States Department of Agriculture (USDA)-funded project with processing tomatoes is underway with collaboration of Gene Miyao, UCCE Yolo, Solano and Sacramento counties, Zheng Wang, UCCE Stanislaus County and myself, in addition to proprietary research being conducted by the industry. Rootstocks for heirloom tomato production are being evaluated by Margaret Lloyd, small farms advisor with UCCE in Yolo, Solano and Sacramento counties.

Acknowledgements

The California Department of Pesticide Regulation provided partial funding for this project but does not necessarily agree with any opinions expressed, nor endorse any commercial product or trade name mentioned. In addition, this project was supported by the Specialty Crop Block Grant Program at the U.S. Department of Agriculture through Grant 14-SCBGP-CA-0006. The contents of this report are solely the responsibility of the authors and do not necessarily represent the official views of the USDA. We also thank our grower-cooperators (Live Oak Farms and Pacific Triple E), Growers Transplanting Inc. for producing grafted plants, and the following companies that supplied the seeds: Monsanto/De Ruiter Seeds, Gowan Seed Company, Harris Moran Seed Company, and Syngenta Vegetable Seeds.

For more information:

Additional information on our field trials:

https://ucanr.edu/sites/veg_crop_sjc/Grafted_tomatoes/

Detailed information on how to undertake vegetable grafting is available at: http://www.vegetablegrafting.org/resources/grafting-manual/

List of tomato rootstocks including disease resistances and where to order seed: http://www.vegetablegrafting.org/resources/rootstock-tables/solanaceous-rootstock-table/