Whether your grapes are destined for wine, raisins, juice or the table, the job of the grapevine is to capture energy from the sun and use it to convert CO2 and H2O to carbohydrates and O2. Maximizing this process begins at budbreak and leads to larger, higher-quality crops. To have the greatest influence, a wholistic understanding of plant nutrition and crop production need to be engaged to ensure that every dime of fertilizer applied best serves its intended purpose. This is where the Five Rs of Plant Nutrition enters the decision-making process.

By combining knowledge from plant physiology, soil science, microbiology and chemistry, core principles of plant nutrition arise that affect fertilizer use efficiency, yield and quality. The Five Rs provide this science-driven approach in a memorable way that helps to confirm or guide nutritional decisions. A series of checks, the Five Rs ensure that the applied nutrients get into the plant when and where they are needed with minimal unintended nutrient interactions or losses. When framed as a question, the Five Rs can be stated as:

For my application, is this the:

- Right Nutrient?

- Right Time/Crop Stage?

- Right Form?

- Right Nutrient Mix?

- Right Place in the Plant?

The order of the Five Rs is easily re-organized to fit a given scenario, and when focusing on a specific growth period, considering the right time/crop stage first has the most value.

Right Time/Crop Stage

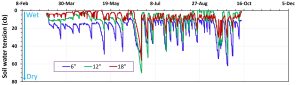

Early spring is a critical period for grapevine growth and development as the foundational support components of the plant and crop (xylem, phloem, initial leaves and new roots) are created. This timing is also very challenging because the ability of the plant to obtain and move the needed nutrients from the soil is hindered by low soil temperature and low atmospheric evaporative draw.

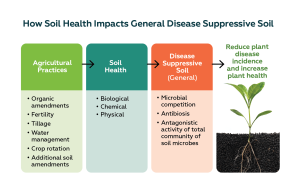

Cold soils inhibit microbial growth and function, preventing the cycling of nutrients from plant-unavailable to plant-available forms. Similarly, mineral solubility in the soil-water solution is also reduced as soil temperatures decline.

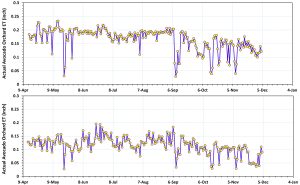

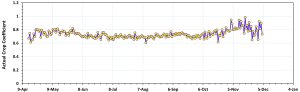

Evapotranspiration is the primary mechanism for the movement of nutrients between the soil and the plant. When air temperatures decrease, so does the amount of moisture a given volume of air can hold as does the rate that the air can cause evaporation. Coupled with the small surface area of new growth, very low levels of evapotranspiration result.

The classical thought that soil nutrient stores alone can support optimal plant growth and development early on is brought into doubt, and other fertility decisions need to be considered. Other non-evapotranspirational mechanisms exist within the plant to mobilize and move stored nutrients but should be viewed purely as supplemental.

Right Place in the Plant

Just as important as what nutrient to apply and when to apply it is identifying the most efficient or appropriate place in the plant for the application. As addressed above, early spring conditions result in the soil being a poor nutrient source with low delivery efficiency. Yet, nearly all nutrients found in or used by the plant over a growing season were sourced from the soil via the roots. So then why is “Right place in the plant” a core principle? When nutrient demand timing and nutrient delivery limitations meet, the end goal of maximizing economic yield focuses less on ‘where is the nutrient found?’ and more on ‘where are the nutrients needed and what is the best way to deliver them?’ Hint: The answer isn’t always via soil application.

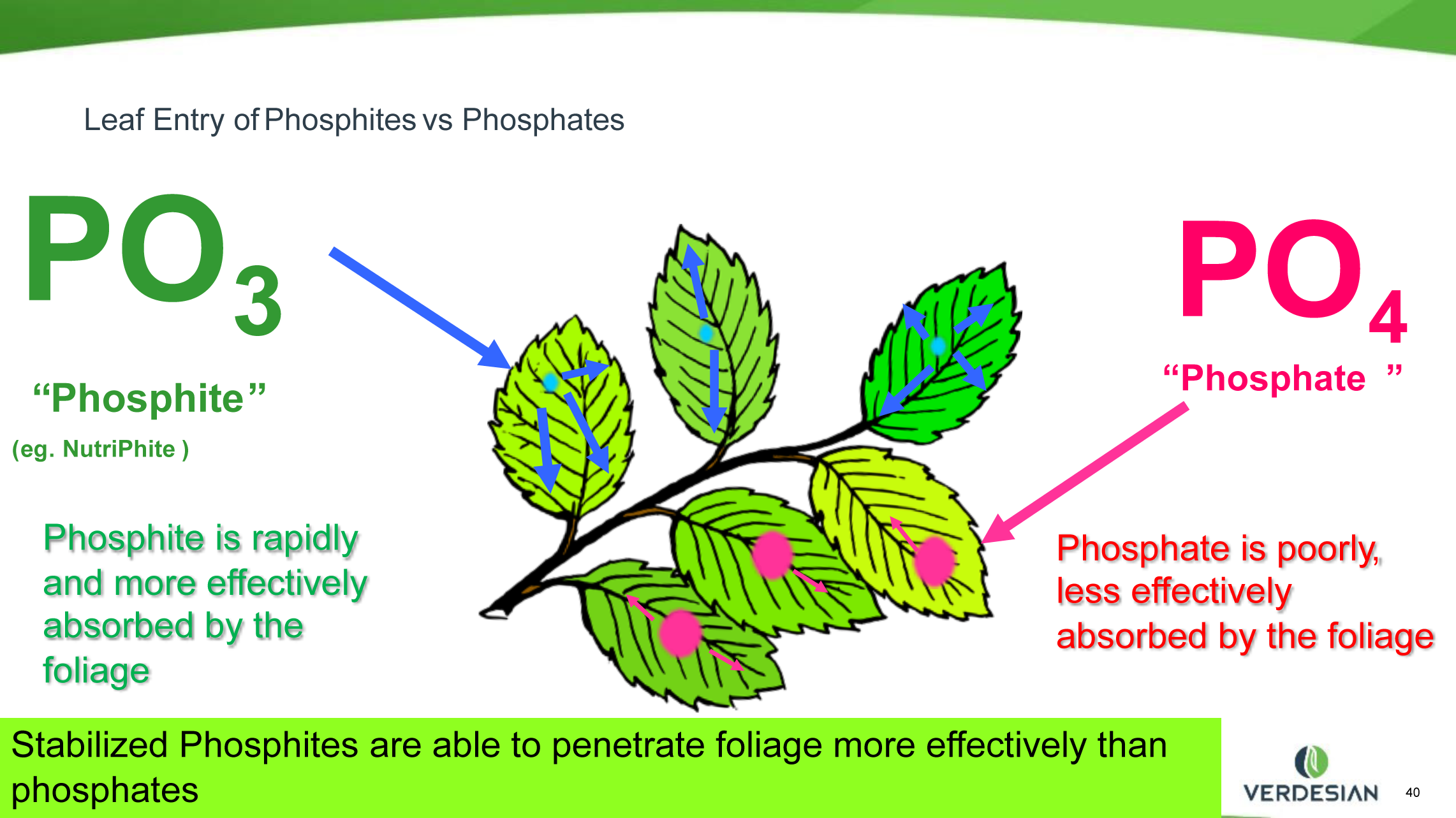

For most nutrients, what is found in or applied to the soil meets the volume requirements of the plant, but often soil conditions during the demand period or interactions with other nutrients limit their availability. Even in soils with perfect nutrient conditions, periods still exist where only foliar nutrient applications can meet the limited window of nutrient demand. Post-budbreak is such a time and pre-bloom, bud differentiation, set and berry development, post-veraison and postharvest periods all see benefits from timely foliar applications. During these periods, foliar nutrient applications can achieve results that the soil cannot deliver. And to go a step further, foliarly applied nutrients can uniquely alter nutrient ratios or balances within the plant in ways that cannot be achieved economically, or potentially at all, through the soil.

However, just as the soil cannot deliver all nutrients at the right time, the volume of macronutrients needed cannot be delivered solely through foliar feeding. In the end, some combination of both foliar and soil-based applications for most nutrients will be necessary to meet the quantities and timing required for high-level production.

Right Form(ulation)

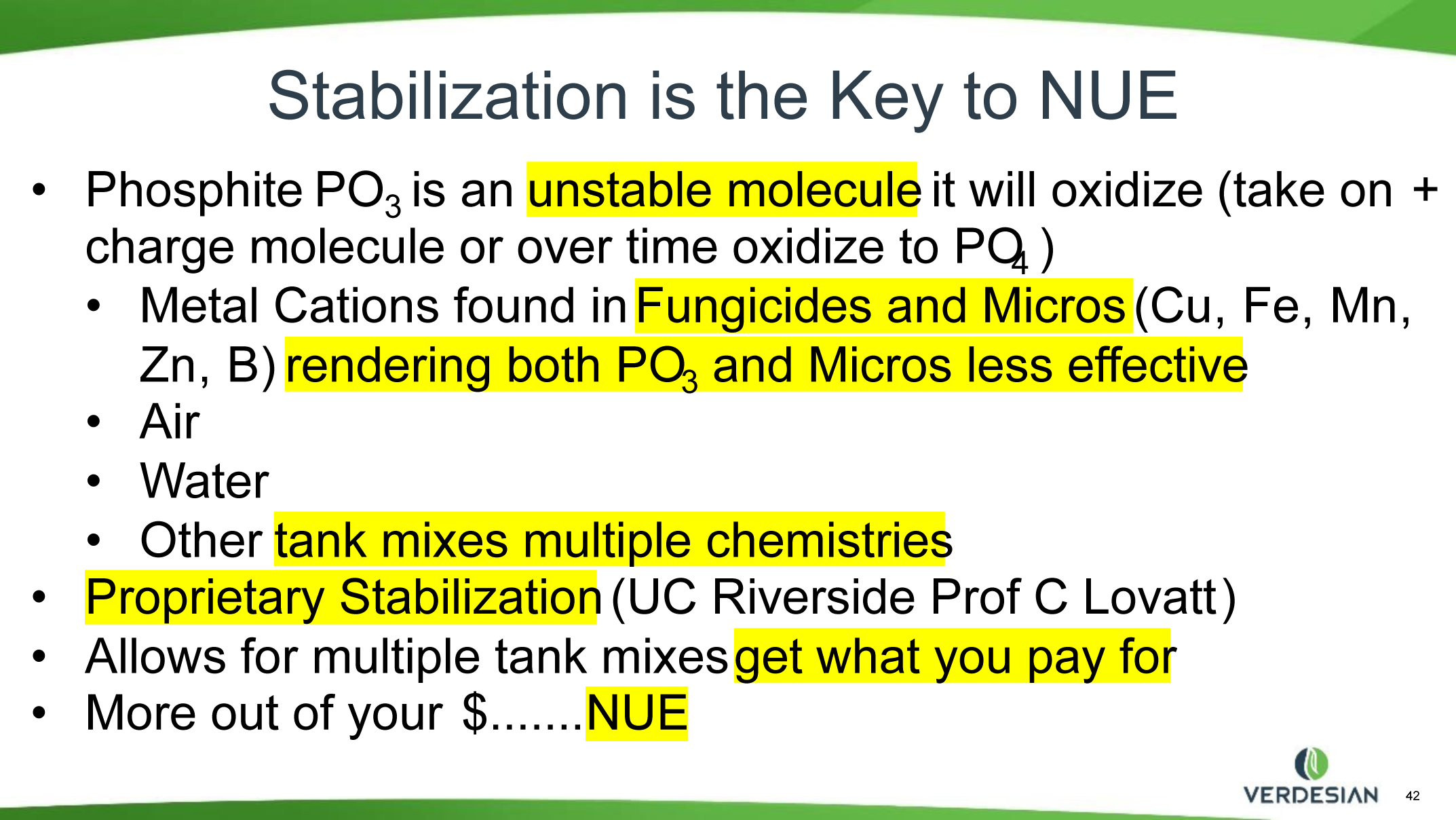

The soil and leaf environments to which nutrients are applied are extremely harsh, albeit in almost opposite ways. This article will not go into specifics, but generally, foliar applications dry quickly, are exposed to comparatively high oxygen concentrations and wide-ranging temperatures, and are bombarded with solar radiation. The soil, on the other hand, is very chemically and physically active at the molecular scale and is teaming with life that needs many of the nutrients for its life cycle that our plants require.

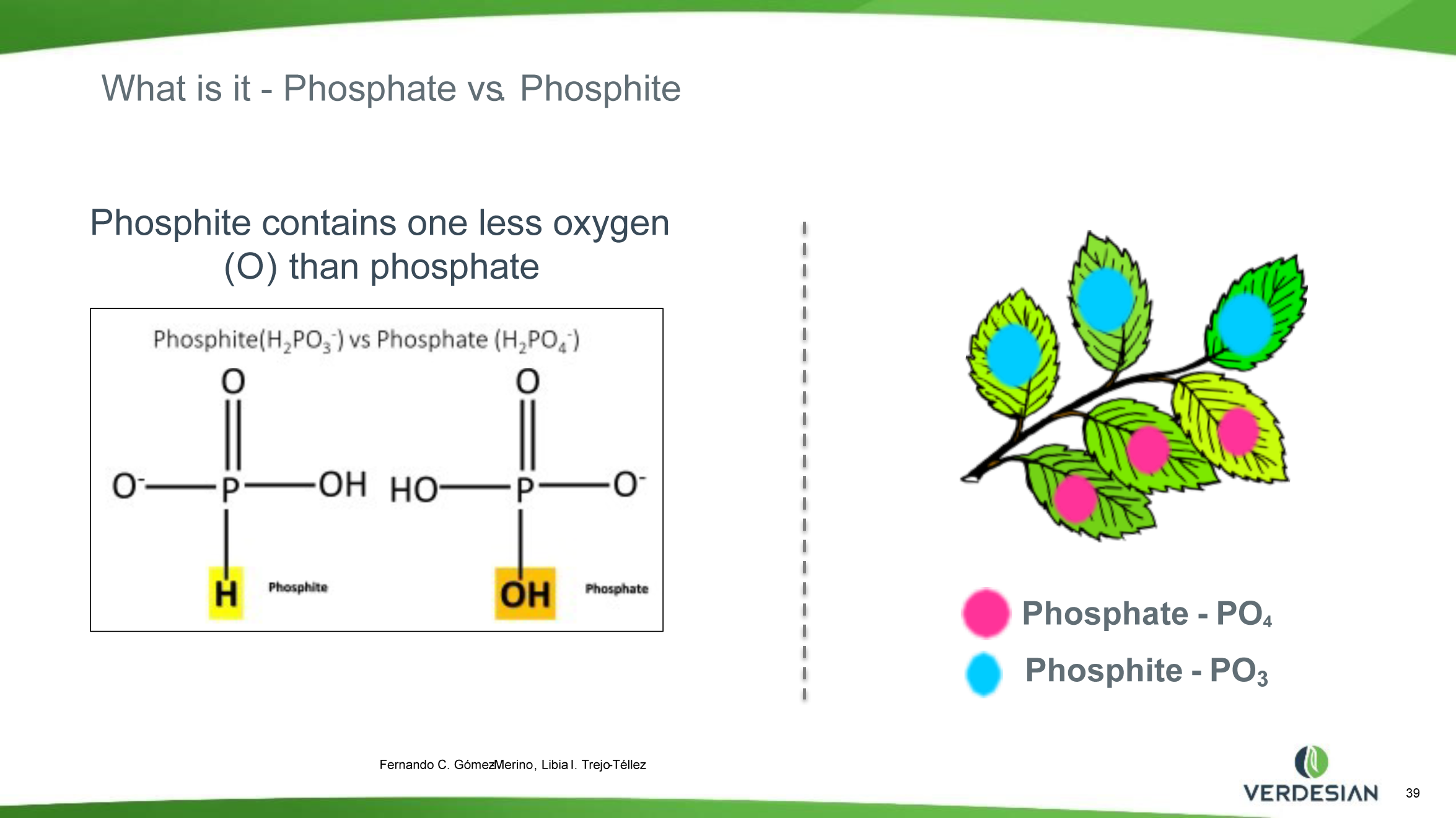

Nutrient products are available as various compounds that can be organized roughly into four formulation groups: insoluble salts, soluble salts, chelates and complexes. Ideal use scenarios can generally be defined for each formulation group, and nutrient stability and uptake performance rely heavily upon where (right place) they are applied.

The main points to understand are 1.) there is no “magic bullet” formulation possessing very high performance as a nutrient delivery vehicle in both soil and foliar applications; and 2.) something else is always competing with the plant to acquire applied nutrients or acting against the formulation of the nutrient, decreasing its availability to the plant.

Insoluble salts: carbonates, oxides, hydroxides

Nearly or completely insoluble in aqueous solutions but micronize well. Foliarly, they coat tissues like paint and are highly effective reflectors/blockers of sunlight. As such, they are often used to prevent sunburn or sunscald of plant tissues. Foliar nutrient delivery performance is very poor. Slow conversion to plant-available forms in the soil results in poor performance.

Soluble salts: sulfates, nitrates, acetates, chlorides

Soil applications usually perform very poorly, but low cost can offset the inefficiency. Foliar performance is poor as uptake is slow, and excess accumulation of the companion anions (SO4, NO3, C2H3O2, Cl) elicit stress responses in the plant or are otherwise problematic.

Chelates: EDTA, EDDHA, EDDHSA, citric acid, amino acids

Synthetic, EDTA-type and similar are generally large, highly water-soluble materials that perform exceptionally well in soil applications. They are toxic to plants and soil organisms, however, and can solubilize heavy metals in the soil, causing accumulation in plant tissues. They are not great foliars.

Conversely, citric and amino acid based chelates perform well when applied foliarly and are less toxic. Stability is an issue in soil applications compared to EDTA-type chelates.

Complexes: dextrose-lactose, mannitol, glucoheptonate, lignosulfonate

Poor performers in soil applications, these naturally derived materials make average to exceptional foliar delivery vehicles. Molecular weight and size of the complex affects performance. The complexing compounds of some offer carbon skeletons that are easily assimilated by the plant once the nutrient is removed.

Right Nutrient/Nutrient Mix

While not always grouped together, the right nutrient and the right nutrient mix are closely related. Plant nutrient demands fluctuate over the season, and nutrient-to-nutrient ratios shift subsequently. Nutrient-to-nutrient inhibitions, synergies, antagonisms and stimulations exist and must be accounted for as not all nutrients work well together in the plant at the same time.

In our budbreak to pre-bloom vineyard, demand for all nutrients except potassium are high, and calcium and phosphorus are both needed early on. But Ca and P antagonize each other, decreasing application and assimilation efficiency. So, which do we apply? If we assess the right time and right place components, foliar application of Ca makes sense since it moves exclusively with the transpiration stream and as is needed in the leaves to initiate cell division and develop cell walls. P on the other hand provides the energy needed for cell division and other growth functions to occur. Under ideal circumstances, we could apply P foliarly today and Ca foliarly in three to seven days and see the greatest benefit. Practicality doesn’t often allow for this type of application situation, and in our attempts to reduce the number of passes through the field, we must apply both simultaneously.

Tie-ups and antagonisms in real-world agriculture are inevitable and will occur in the spray tank and in the plant. But synergies and gains in efficiency and yield will occur from a little time, effort and application of the Five Rs into your nutritional program.