Citrus mealybug, Planococcus citri, has become an increasing concern for citrus growers in California. This pest feeds on plant sap on all parts of plants, including flush, twig and fruits, reducing tree vigor and affecting yield. Mealybug produces copious amounts of honeydew while feeding, which is discharged on leaf and fruit surfaces where sooty mold grows. Mealybug infestations may also lead to serious ant invasions as sugar-feeding ants tend mealybugs and protect them from natural enemies, interfering with biocontrol efforts. Regular, early season monitoring is essential for detecting initial infestations and implementing timely control measures.

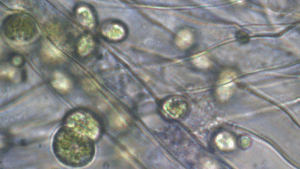

Citrus mealybugs are soft, oval, flat, distinctly segmented insects covered with white mealy wax, giving them a dusted-in-flour appearance. Females lay eggs in egg sacs loosely held by white cottony flint (Fig. 1). Crawlers, when hatched, are yellowish in color but soon develop a waxy covering once they start feeding. Adult females are 3 to 5 mm long and wingless with pinkish bodies covered in white mealy wax. Males are winged and take a longer time to develop than females.

California’s Central Valley has approximately 75% of the state’s citrus production acreage. Mealybugs are increasingly becoming a difficult pest to manage and are expanding in acreage and have been reported in all citrus varieties grown in the Central Valley. Mealybugs are not only a direct pest that causes yield and cosmetic damage to fruit but also a phytosanitary concern for exports to markets such as Korea, China and Australia, where zero-tolerance policies apply.

Effective monitoring of mealybug enables:

• Early detection to prevent population outbreaks

• Timely control decisions, reducing overall pesticide usage

• Accurate pest history tracking for developing long-term sustainable management methods

When to Monitor?

Monitoring should begin in early spring (March/April) and continue through postharvest (November to March). While mealybugs are most active during summer and fall, warm microclimates in orchards can support winter reproduction, especially if average daily temperatures stay around 60 degrees F.

What to Monitor and How?

Mealybug overwinters as adults and eggs (within the egg sacs). Early in the season, look for mealybug egg sacs/adults inside the tree canopy on trunk and inner branches or between fruits. Use a hand lens to inspect for crawlers and first instars. They intersperse via wind, or by ants, birds or equipment. As the season progresses, mealybug moves to young fruit and infests fruit.

Early season (January to March)

• Mealybugs overwinter as adult females and eggs.

• Focus monitoring in protected areas (e.g., deep canopy, bark crevices, inside fruit clusters).

• Use a hand lens to inspect for egg sacs and first instars.

Spring to early summer (April to June)

• Crawlers hatch and begin dispersing via wind, ants or machinery.

• Monitor trunk, scaffold limbs and new flush for early populations.

• Begin pheromone trapping for male activity.

Summer to fall (July to December)

• Populations move onto developing fruit.

• Mealybugs feed on calyx and peduncle, sometimes clustering around fruit stems.

• In high-pressure areas, they may spread across the entire fruit surface.

• Multiple overlapping generations may be present by fall.

Pheromone trapping: a valuable tool

For early detection, especially in orchards with no

known infestation:

• Install pheromone trap cards (Fig. 2) in mid-canopy

(one trap per 10 acres).

• Begin trapping in April and replace lures every five weeks.

• Interpret with caution as catches may reflect nearby orchard activity as well as local emergence.

Hotspots to monitor

• Ant activity zones: Ants often lead to hidden mealybug clusters.

• Wind machines: Areas beneath may harbor infestations due to insect dispersal.

• Previously infested trees: Key indicators of localized reinfestation.

If your orchard currently does not have citrus mealybug, it may be difficult to determine where infestation starts. In that scenario, you can do the following:

Use a pheromone lure and a trap card to monitor for citrus mealybug males, one card in the middle of the orchard per 10 acres. Change lures every five weeks. Begin monitoring in April (Fig. 2). Be mindful because flyers may come from nearby orchards.

‘Mealybug infestations may also lead to serious ant invasions… interfering with biocontrol efforts.’

Check any areas with ant activity near the wind machines for any signs of mealybug activity as ants and birds can carry and relocate citrus mealybug.

If your orchard has a history of infestation, it is a good idea to begin monitoring those previously infested trees. Because mealybugs move to different parts of the plants as the season progresses, monitoring is season-dependent.

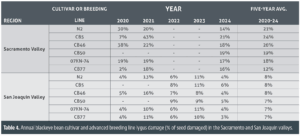

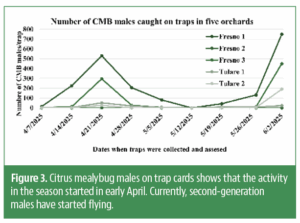

What is Happening with Citrus Mealybug Populations in The Central Valley?

Recent monitoring across five

Central Valley orchards provides

the following insights:

• First male flights: Detected in early April, peaking by the third week of April (Fig. 3).

• Current (mid-June) population: Dominated by egg-laying females on fruit peduncles and inner canopy branches (Figs. 4 and 5).

• Second-generation male flight: Now beginning. We have started catching males on the traps. Adult and egg-producing females are present as of June 9, 2025.

Citrus mealybug has become an increasingly complex pest of citrus in California’s Central Valley, with implications for tree health, fruit marketability and yield loss. A seasonally adjusted, site-specific monitoring plan can be helpful in staying ahead of population growth and ensuring effective, reduced-risk pest management.