Blueberry production acreage in the U.S. is expanding. Across the country, commercial blueberry growers are increasingly using over-the-row (OTR) mechanical harvesters (MH) to pick their blueberries for fresh market (Figure 1). Growers everywhere are experiencing difficulties in finding sufficient labor for hand harvest operations and due to the rising costs of labor. Harvesting blueberries with OTR harvesters can significantly reduce the overall cost of harvesting to a fraction of that needed for hand harvesting (HH) and workers needed for harvest operations from about 500 hours of labor per acre per year to as little as three hours of labor per acre per year. However, compared to hand harvesting, OTR harvesting causes more berry loss due to falling on the ground and green/red berries are harvested along with ripe, blue fruit.

Detailed field testing of OTR harvesters for picking blueberries for the fresh market was conducted nearly 30 years ago in Michigan. That research in South Haven, Mich. evaluated the quality of blueberries harvested by hand and by four rotary and slapper harvesters that were used by growers at that time to harvest blueberries for processing. MH blueberries were sorted at the packinghouse (Figure 2).

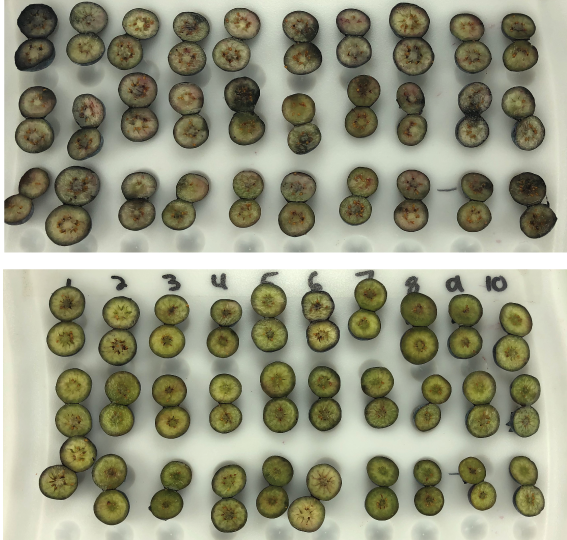

The most significant findings were a high percentage of detached blueberries had impact damage (Figure 3) and more than 20% of detached blueberries fell on the ground. The bruise damage was attributed to iImpact to the fruit created by the rapid actions of shaking rods and detached berries landing on the hard catching surface. Those studies revealed that blueberries harvested by the machines had a high percentage of blueberries with more than 20% of sliced surface area showing bruise damage (Figure 3 and 4). Also, MH blueberries were much softer compared to hand harvested fruit. Their conclusion was that MH blueberries should not be cold-stored for more than two weeks while HH blueberries could go in controlled atmosphere storage for six weeks and air-shipped to Europe in excellent condition.

Soon after, USDA engineers developed an experimental harvester called the V45 harvester designed specifically to harvest fresh-market blueberries. It used a direct-drive shaker with an angled, double-spike-drum, a unique cane dividing and positioning system to push the canes out diagonally and cushioned catching surfaces to harvest fruit with minimum damage. With the V45 harvester design, the detached blueberries dropped less than 15 inches onto a soft neoprene sheet glued to a hard catch plate and soft sheet over the conveyor belt.

These soft surfaces reduced impact force on the fruit detached by the V45 harvester. However, gluing a soft surface onto a hard surface has proven to show little reduction in bruise damage when harvesting is performed with conventional harvesters with two vertical drum shakers and berries falling more than 30 inches. Only five V45 harvesters were sold by the now defunct B.E.I Inc. (South Haven, Mich.), although it was thought to have good fruit selectivity (low green fruit removal) compared to slapper models, little ground loss (fruiting cane pushed away from the crown) and superior quality over existing commercial harvesters at the time with two vertical drum shakers and either a metal or hard plastic catch surface.

Sometimes, the fruit harvested by the V45 harvester had quality as good as commercially HH fruit. Its limitations were: 1) It needed to be driven much slower to avoid damaging bushes; 2) It could not harvest trellised rows or those with overhead sprinklers; and 3) It could not harvest all varieties, especially those with stiff, upright canes like ‘Jersey’ and many rabbiteye cultivars. The Fulcrum harvester made by A&B Packing Equipment (Lawrence, Mich.) has features like those of the V45 harvester.

In the last ten years or so, U.S. blueberry farmers targeting the fresh market have been facing challenging economic situations (e.g., rising cost of hand picking, shrinking labor force, global competition, etc.) They and other specialty crop farmers have a greater interest in using automation and OTR machines to harvest their crop. The authors of this article have participated in different aspects of machine harvesting and sorting of blueberries to reduce the amount of internal bruise damage and in packing line sorting technology and damage detection systems to improve the quality of packed fruit. Several blueberry MH manufacturers (e.g., Oxbo International, Lynden, Wash.; A&B Packing Equipment, Lawrence, Mich.; BSK, Serbia; and FineFields, the Netherlands) have put more efforts devoted to developing MH systems that would impart low or no bruise damage so that fruits can be packed for fresh market. Following is a summary of recent developments in MH.

Bruised Berries from Mechanical Harvesting

Most OTR harvesters currently available are better suited for harvesting processed blueberries because they can cause excessive fruit damage. However, OTR machines have been used to pick blueberries for fresh market. In these instances, the fruit should be packed and transported to consumers as quickly as possible. When blueberries are HH, typically the picker gently picks ripe fruit selectively. In Chile and China, for example, ripe berries are picked individually to obtain high fresh quality.

In the Pacific Northwest and elsewhere in North America, ripe fruit is often harvested by rubbing fruit cluster or sometimes by “tickling” them between the thumb and index finger and catching the detached berries in the palm and then placing them in a small harvesting bucket. In contrast, MH involves the shaking of the entire bush with rapid action of shaking rods to move canes back and forth. The cane movement causes ripe berries that need less fruit removal force than green/red berries to be displaced from the fruit stem (pedicel) and fall onto catching surfaces. Experienced MH operators make slight adjustments on machine settings to obtain good selectivity (minimize green/red berry removal and maximize ripe fruit removal).

The blueberry bush can range from 3 to about 6 feet tall with fruit located from the tip of the canes to branches near the ground, which causes the berries located on the top part of bush to fall as much as 50 inches. When an OTR harvester picks blueberries and fruit falls from that height onto plastic catch plates and conveyor belts, one can hear berries hitting the hard catch surfaces.

Based on this simplified description of the blueberry MH process, it was apparent that the interaction between the machine and fruit should be better understood. To do this, we used a custom-made miniature electronic sphere called the BIRD (blueberry impact recording device developed at the University of Georgia) to measure the fruit impacts during MH process in 2010 and 2011. The BIRD sensor for this study weighed 14 g. The later version, BIRD II, was built to closely approximate the size and weight of a large blueberry (9/16-in diameter and weighed 6 g) (Figure 5).

Along with documenting fruit impacts with a BIRD, a closeup video camera recorded the harvesting to pinpoint critical control points where most impacts were created. The results showed that the drop to the plastic catch plates on the harvester accounted for over 30% of all impacts on the BIRD, followed by the drop from the grading belt on the harvester into an empty lug (20%). When the lug is filled with blueberries, fruit-to-fruit impacts occur, which are much lower than when the fruit fall into an empty lug.

Impacts created by the conveyor, including secondary bounce from the catch plates, and shaking rods combined for another 25% of recorded impacts. The remaining 25% of impacts that occurred before the sphere contacted the catch plate were classified as obscured impact events which could not be identified clearly from the video and were attributed to contact with the shaking rod, branches and the vertical tunnel panels. These measurements suggested that the most significant reduction in fruit impacts could be achieved by 1) Modifying the catch plates; 2) Reducing drop heights, either by restricting bush size, placing catching surfaces closer to the fruit or decreasing drop heights at other transition points; and 3) Placing softer surfaces at the transition points (e.g., at transfer points in the fruit handing equipment on the top of platform.)

The two parts of the impacts include the number of encounters between the sphere and different surfaces of the harvester and the magnitude of these impacts. In our study, the harvesting process was documented with video that recorded time-stamped impact events with the larger, heavier BIRD I sensor. Using these parameters, the OTR MH process was divided into four phases: Phase I (detachment and falling), Phase II (fruit hitting the catch plate/conveyor belt), Phase III (elevation from the conveyor/transfer belt to the top platform and conveyance through a trash blower) and Phase IV (dropping from the conveyor belt into the lug).

Results showed that for the rotary drum shaker, the BIRD sensor recorded an average of 18 impacts in Phases I to IV. During Phase I, it is assumed blueberries detached by fast-moving harvesting rods that shake left and right, impact branches as they fall and/or are flung out to the side panel. There were about five impact events in Phase I, but magnitudes of these impacts proved to be less significant than initially assumed. In Phase II, the BIRD contacted the catch plate and usually only one or two events were recorded. The magnitude of the impacts in Phase II was extremely high compared to impacts recorded in Phases I, III and IV. Our results strongly suggested that the high impact that the falling blueberries receive at the point of contact with the catch plate injures the fruit, resulting in fruit softening and larger bruise while the fruit is in storage (Figures 3 and 4).

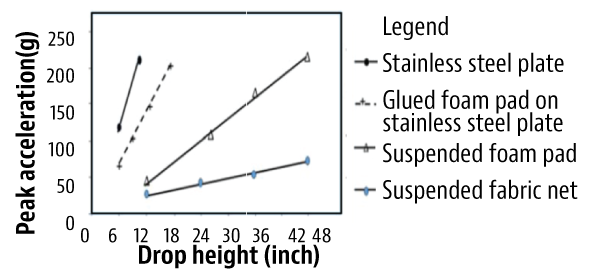

Further analysis was performed by dropping the large, heavier BIRD I sensor onto a hard-plastic catch plate from different heights (6, 12, 24, 36 and 48 in) (Figure 6). As expected, the impact values (peak acceleration at impact (g) increased sharply linearly with increasing drop height, ranging from 280 g at 6 in to about 800 g at 48 in (data not shown). In subsequent studies, impact measurements were made using the smaller and lighter-weight BIRD II sphere by dropping onto soft surfaces created by placing cushioned padding on top of the hard plastic plates or by suspending the soft material (no hard surface underneath.)

A wide range of impact values were obtained depending on the hardness of the catch plate (Figure 6). Impacts greater than 200 g were recorded on hard surfaces such as a stainless-steel sheet and a plastic catch plate even when the BIRD II was dropped from a height less than 30 cm (12 in). Gluing a soft surface to a hard surface reduced impact; however, this type of surface still created high impact above a one-foot drop height such that blueberries falling 30 inches onto such a surface would still be bruised. For example, the suspended foam sheet we used in our harvest-assist blueberry picking machine in 2017 generated less than 200 g even when the drop height was 42 in, but well above the 120 g at which ripe blueberries can be bruised by impact force. Only the netted fabric that acted like a hammock produced low enough impact force and kept the blueberries from getting bruised even when the fruit was dropped from a 48-in height. Thus, it was thought that replacing the hard, plastic fruit catching and collection surfaces with soft and durable catching surface materials and plate design features that prevent soft surface from contacting any hard surfaces underneath had the potential to improve the quality of MH blueberries and reduce bruise damage associated with high mechanical impact.

In terms of mechanical impact to blueberry fruit, our research has shown that bruise damage and the loss of firmness in MH fruit can be decreased by reducing space between blueberries on the bush and the catching surface to 12 inches in the case of hard plastic fruit catching surfaces or by modifying the fruit catching surfaces to create a softer fruit landing surface. Ideally, the fruit catching surface should not exceed 120 g impact even when the BIRD II is dropped from a height of 48 in (equivalent to the distance between the top of a large mature blueberry bush and catch plates on the harvester).

The design of soft surfaces can be achieved by either incorporating netted material or a soft “rubber” sheet with no hard surfaces beneath for catching the fruit (Takeda and Wolford, U.S. Patent No. 9,750,188 and the Oxbo SoftSurface kit). For example, even with a soft surface insert in a hollowed-out plexiglass catch plate, the margins of the plate contributed to more than 20% of the exposed surface area. In addition, catch plates on the harvester overlapped with adjacent plates and rested on top of another plate. The outline of the plate below another created about 10% additional hard surfaces.

When blueberries are HH, the packout is about 95% or better and fruit usually have little or no internal bruise damage (Table 1). The packout of MH blueberries is lower and typically ranges from 70% to slightly more than 80%. The remaining 20% consists of soft, overripe and immature green- and red-colored berries.

Commercial packing operations, for the most part, do not check for internal bruise damage in their MH blueberries. However, close inspections of MH blueberries packed into clamshells after sorting on commercial packing lines revealed berries were bruised (Figure 3, see page 4). Our studies evaluated different catch surface designs by inserting soft, flexible material to reduce internal bruise damage. We did record improvements in packout. However, neither the improvement in packout nor berry firmness approached that of HH fruit in the case of varieties Duke, Draper or southern highbush blueberry (SHB) Optimus even when they were harvested with OTR machines equipped with soft, flexible catch surfaces. The only exception to date has been the variety Last Call, where MH produced the quality approaching that of HH berries. MH of SHB Optimus produced higher-quality packout than other SHB varieties, such as Jewel, Star and Farthing, but even Optimus should not be cold-stored for more than one week. Our studies have shown that fresh market pack-out can be increased by installing a soft catch surface on the harvester, but the quality of HH blueberries has been better.

Cultivar Susceptibility

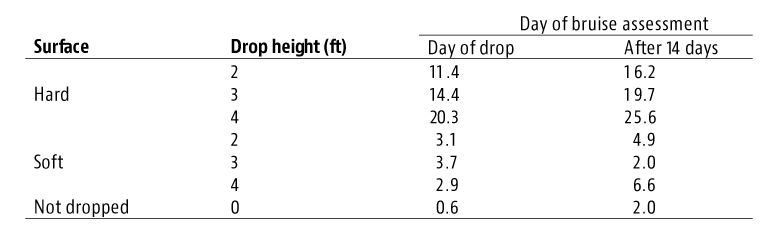

In a study conducted in Oregon, the susceptibility of 11 blueberry cultivars to impact damage was determined by dropping the fruit from 2-, 3-, and 4-foot heights onto a hard, plastic catch plate. Bruises developed more rapidly in rabbiteye cultivars (Ochlocknee, Powderblue and Overtime) than in northern highbush (NHB) and SHB cultivars. NHB cultivars Aurora, Cargo, Draper and Last Call had the least amount of bruising after two weeks in cold storage. Blue Ribbon, Legacy and Liberty had a moderate amount of bruising.

These studies showed that simulated drop tests are useful in determining the potential of varieties for long-term cold storage and, more importantly, their potential to MH for fresh market. In a study in 2020 in Oregon, Draper and Legacy were MH with two OTR Oxbo harvesters, one fitted with and the other without the SOFTSurface kit. To date, the challenge for Oxbo Corporation and other machine manufacturers has been to procure soft materials that meet food safety standards and are durable for harvesting blueberries.

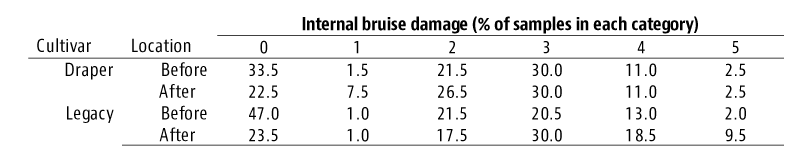

The preliminary findings of this study were: 1) Machine harvesting with the SOFTSurface kit reduced fruit internal bruise damage in both Draper and Legacy fruits compared to those harvested with the unmodified OTR harvester as shown with a laboratory test (Table 1); 2) Draper and Legacy fruit harvested with the machine fitted with the SOFTSurface kit and sampled before sorting in the packing house were firmer compared to fruit harvested by the unmodified harvester; and 3) After one and two weeks in cold storage, there was no difference in firmness of berries harvested by machines fitted with and without the SOFTSurface kit.

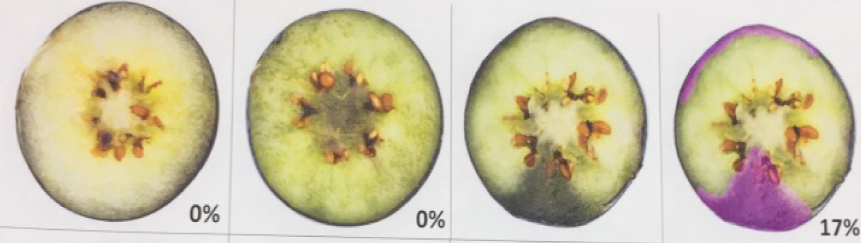

We found that fruit firmness-based sorting by itself may not be a good predictor of berry quality when MH blueberries are cold-stored for two weeks or more, but both Draper and Legacy blueberries picked by the OTR machine fitted with the SOFTSurface kit maintained better fruit firmness (>160 g/mm) values and lower internal bruise ratings in cold storage (Table 1). The improvements in fruit quality may well have been from a 70% reduction in hard catch surface area in the SOFTSurface kit compared to the hard polycarbonate fruit catching surfaces in the regular harvesters. A laboratory test determined the effects of dropping blueberries from different heights onto either a hard (e.g., polycarbonate catch plate on conventional harvesters) or soft catch surface (e.g., prototype SOFTSurface kit) on internal bruise development (Table 1). Blueberries were sliced to visually assess bruise damage on the day of the drop test and after cold storage for two weeks.

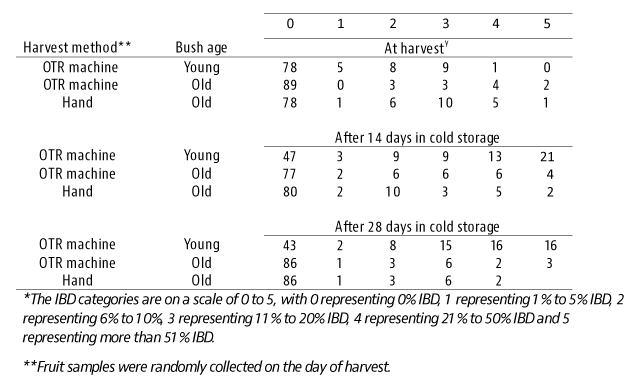

Young (~3-ft-tall) and mature (6-ft-tall) trellised Last Call blueberry plants were either HH or picked with a modified OTR machine. Fruit samples from both methods were manually sorted and evaluated for internal bruise damage on the day of harvest and the remaining samples were placed in cold storage. Cold-stored samples were taken out after two and four weeks and evaluated for internal bruise damage (Table 2). On the day of harvest (zero days after harvest), about 80% of blueberries showed no bruise damage, and the remainder showed damage ranging from 1% to more than 50%. There was little change in internal bruise for samples from matures bushes that were either HH or MH. However, there was a dramatic decline in the percentage of fruit with no internal damage among the samples from machine harvesting of young plants.

Our field observations of the Last Call bushes used in this study indicated that the canes of young plants were upright during the harvest and detached fruit fell straight down. In contrast, on the taller, mature bushes, the canes had grown well above the height of the trellis and they were leaning outward at the time of harvest. This placed the fruit away from the crown and less than 30 inches above the catching surface and may have contributed to reducing mechanical impacts in terms of numbers and magnitude, thus reducing the amount of internal bruise damage.

Sorting Out Bruised Berries

Blueberry growers in the Pacific Northwest and in Chile have expressed an interest in machine harvesting blueberries for the export market. The consensus among them is that the varieties for the export market must be firm and arrive at the destination in excellent condition after more than three weeks of cold storage and a transoceanic travel period. Our machine harvesting research has consistently shown that the MH blueberries generally had more internal bruise damage and shorter shelf life than the HH blueberries.

Commercial optical sorting equipment are now available for grading blueberries. In the last three years, HH and MH blueberries have been processed on commercial blueberry packing lines in Oregon and Washington equipped with an optical sorter (e.g., UNITEC, BBC and MAF). For each packing line, samples of Draper and Legacy were taken from lugs prior to unloading onto the conveyor system, and a second group of samples were collected after the fruit had gone through the optical sorting machine. Samples from both locations were assessed for bruise damage (% bruised area). The bruise data are presented in Table 3 in which the data are expressed in terms of how the samples were distributed (e.g., blueberries with no damage to those that were severely bruised.) The analysis indicated that sorting by optical sorters did not remove blueberries with moderate to severe internal bruise damage.

Next, we compared the blueberry fruit firmness value with the area of internal bruise damage on the sliced surface. One would likely assume that softer fruit will have more bruise damage. Our results and those from a report by Chilean researchers showed that this was not the case as shown by the low correlation coefficient (r-value) for these two fruit quality parameters. Whether the fruit had been collected from the packing line before or after the optical sorting machine, the correlation coefficients for berry firmness and bruise damage were less than 0.4 in NHB cultivars. This suggested that optical sorters in commercial blueberry packing houses were not effective in removing blueberries with internal bruise damage.

Once more in the laboratory, we conducted drop tests in which HH Duke blueberries were dropped from a height of 62 inches to ensure that the samples would be bruised. A hyperspectral imaging system was used to locate and quantify bruise damage in each whole fruit (25 berries at a time). We then measured fruit firmness with a FirmTech II at the site of the bruise impact as determined by the imaging system. Then, the same fruit was rotated and additional firmness measurements were taken at 90 and 180 degrees from the bruised site.

The analysis showed that at the site of the bruise damage, the average fruit firmness was 149 g/mm. However, at the sites that were 90 and 180 degrees from the impacted location, the firmness was greater than 162 g/mm. This meant that a lower firmness value was detected when the damaged area was purposely used to determine firmness, resulting in a much higher r-value between fruit firmness and internal bruise damage values. Fruit that were firm at the time of packing (e.g., >180 g/mm value using a FirmTech II instrument) were found to have internal bruise damage exceeding 15%. In the near future, our research team will sort MH blueberries with this imaging system to separate whole unbruised and bruised blueberries and conduct postharvest quality evaluation for unbruised and bruised MH blueberries to determine the shelf life of each group with an eye toward exporting MH blueberries to distant Asian markets. Of course, taking this non-destructive imaging system from the laboratory bench to integrating it into commercial optical sorting machines for IBD detection and sorting is a challenge facing the machine manufacturers.

Conclusions

More blueberries for fresh market are being machine harvested.

Machine harvested blueberries have more internal bruise damage.

On-going research is developing a better understanding of what causes bruising and working with harvest machine manufacturer to reduce bruise damage.

New sensor technologies for blueberry sorting could assist in reducing bruised berries in fresh packs.

Our research has shown that to make MH more profitable for blueberry growers, the current OTR harvesters must be modified to reduce impact damage and ground loss. Cultivars with superior machine harvestability are being released by blueberry breeding programs, and research must continue to develop equipment capable of harvesting blueberries with less bruise damage. The sorting system on the packing line for MH fruit must be improved with a greater precision to eliminate fruit with severe internal bruise damage. This would ensure that the quality of MH blueberries going into clamshells would be as good as HH fruit. Blueberry growers in some regions can then contemplate having MH blueberries packed for export. Also, proper training and pruning of blueberry bushes to maintain a small crown can increase MH efficiency. These changes will help in making small, incremental improvements in increasing pack-outs and fresh quality of packed blueberries.

Finally, in order for MH blueberries to have quality that is as good as HH fruit, the blueberry industry needs to be willing to make changes by growing superior varieties, modifying how blueberry bushes are grown and harvested, and improving how the fruit is sorted. This will take a concerted effort from growers, breeders, horticulturists, engineers and supply chain specialists. These changes could lead to blueberry fields that look different from what we see today, with radically different ways of harvesting blueberries and technological advancements for sorting blueberries with the goal of improving the quality of MH blueberries going into clamshells.

In terms of harvesting and packing technology, it is envisioned that U.S. blueberry growers will be using robotic harvesting systems in the field or in warehouses with specialized automated or semi-automated harvesting machines that will avoid damaging berries, have better selectivity to reduce green berries picked and sort out over-ripe and diseased berries in the field. In packing houses, new non-destructive technologies are needed that will be capable of analyzing the blueberry fruit surface and below the skin and sort fruit for quality (large size, high sweetness, flavor, bloom, no bruise damage and color). These advances will facilitate market segmentation and high prices as one U.S. and several European blueberry distributors are doing already with HH blueberries.

This research was supported in part by the U.S. Department of Agriculture agencies (Agricultural Research Service (Project No. 8080-21000-028, National Institute for Food and Agriculture (Agreement No. : 2008-51180-19579 and 2014-51181-22471), Agricultural Marketing Service (FY 18 Oregon Department of Agriculture SCBG to WQY and FY18 Washington SCBG to LWD), U.S. Highbush Blueberry Council, Chilean Blueberry Committee and Naturipe Farms Blue Challenge.

Our gratitude goes to blueberry growers and packers in Waldo, Fla.; Alma and Homerville, Ga.; South Haven and Grand Junction, Mich.; Kingsburg and Stockton, Calif.; Hillsboro, Independence and Roseburg, Ore.; and Burlington, Prosser, Lynden and Sumas, Wash., and in Chile who provided much needed in-kind support to the harvest project. A special thanks goes to Oxbo International Corporation which has collaborated with the group since 2014.

Authors are employees of USDA-ARS (FT, fumi.takeda@usda.gov) Oregon State University (WQY, wei.yang@oregonstate.edu), University of Georgia (CL, cyli@uga.edu), Washington State University (LWV, lisa.devetter@wsu.edu) and University of Florida (SS, sasa@ufl.edu and JW, jgrw@ufl.edu).

Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.