Farmers and agronomists have long observed that well-fed crops tend to suffer fewer pest and disease symptoms compared with nutrient-deficient plants. However, few of us turn to nutrient management to actively prevent disease. Just as a healthy diet rich in vitamins and minerals is the first measure in disease prevention in human health, proper fertilization should be your crop’s baseline of defense against pathogens. Balanced nutrient applications and good-quality soil produce vigorous crops capable of warding off disease.

Plants require a balanced supply of 18 essential elements throughout their lifecycle to sustain growth, repair tissue, prevent and resist disease. Deficiencies in macro and micronutrients often lead to impaired cell wall structure and accumulation of metabolic products that attract pathogens. Weakened and leaky cells walls give pathogenic fungi and bacteria easy entry points into the plant and plenty of food to fuel their proliferation.

Disease prevention requires understanding the environmental conditions that favor the pathogen as well as the nutritive additions that can upregulate plant defenses. Macro and micronutrient applications can support disease-free growth by building strong structural support and developing a biochemical environment unfavorable to pathogenic growth.

Nitrogen

In most cropping systems, nitrogen (N) is the most limiting nutrient to plant growth. Adequate N at key growth stages must be supplied throughout the season to help the crop meet its growth and yield potential. N management can also impact disease susceptibility. The type of nitrogen applied, the amount and the timing of the application all affect the soil chemistry and plant physiology in ways that can either favor or suppress infection. N management decisions should be based not only on the crop’s N requirement, but also on the field’s history of disease. The type of pathogens the plants will likely face may determine how to fertilize the crop.

Obligate and facultative parasites are affected by the crop’s N status differently. Obligate parasites, which require a living host for survival, benefit from a high concentration of N in the plant tissue. Stem rust in wheat, club root in cruciferous vegetables and powdery mildew on many crops feed on succulent, living tissue. High N applications increase vegetative growth, increasing the proportion of young susceptible tissue. High N also increases the concentration of amino acids in cells and on leaf surfaces, attracting and feeding pathogenic organisms. Nitrogen-rich plants decrease their production of phenolics and lignin, weakening both structural and chemical defenses against infection. Overfed plants weaken their defenses.

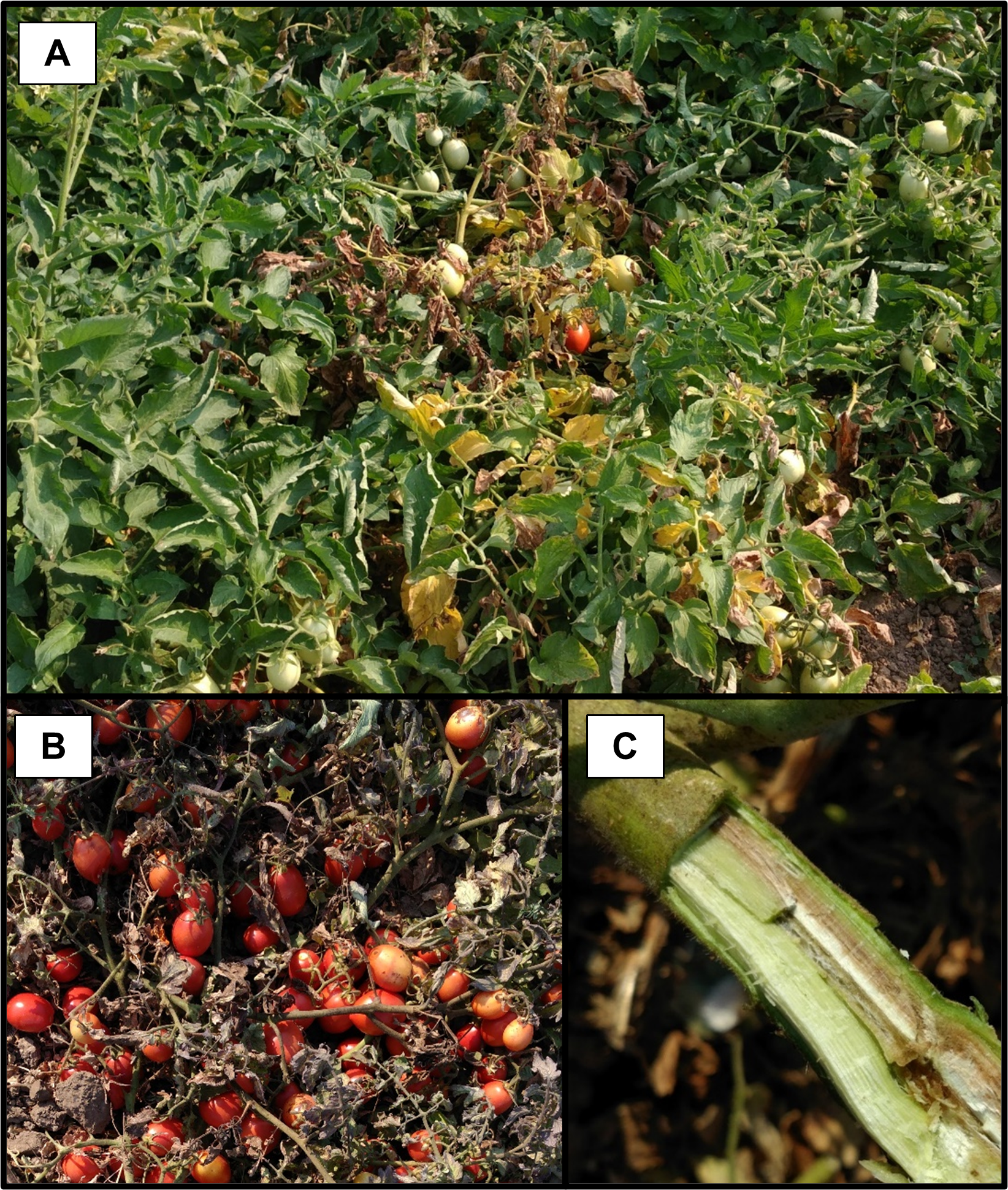

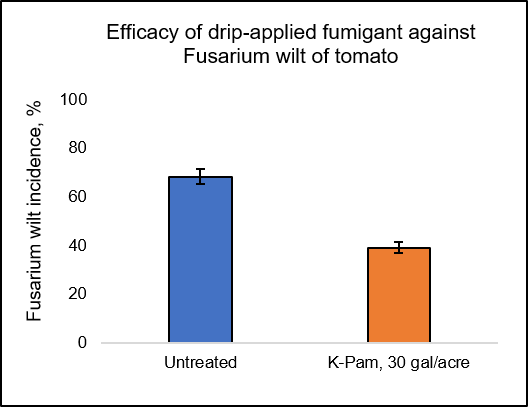

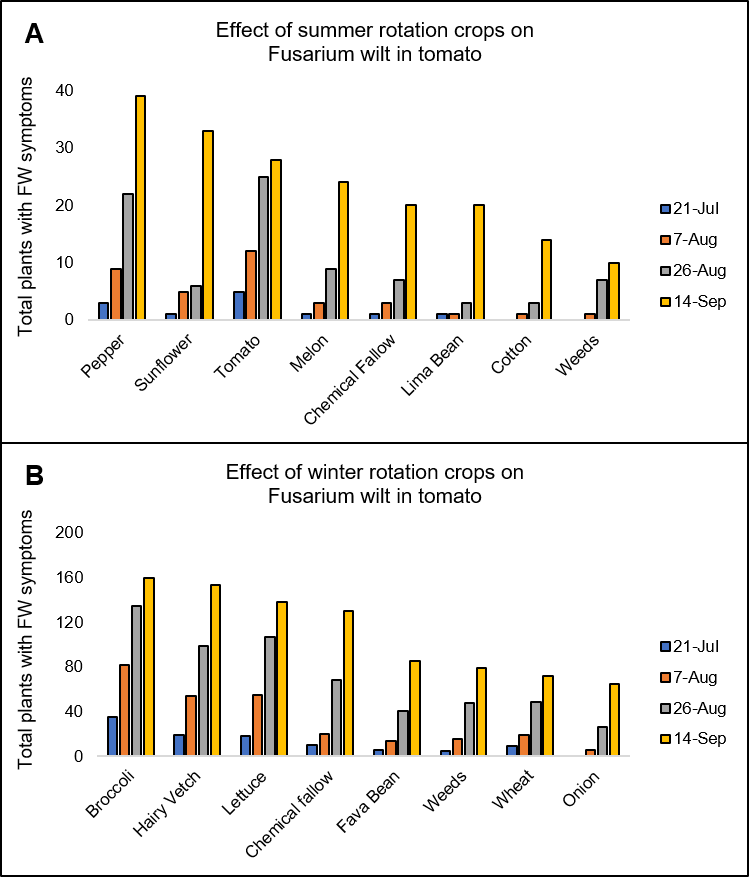

While obligate parasites such as downy and powdery mildew proliferate at high N levels, facultative parasites are sometimes suppressed by higher N content in the crop. Facultative parasites such as Fusarium, Alternaria and Xanthomonas feed on dead or damaged plant tissue. Management practices that can keep plants vigorous and prevent senescence, or cell death, will reduce damage from facultative pathogens. If Fusarium is a known problem in the field, preventing N deficiency should be the first preventative action against infection.

Starving the crop of N will surely weaken the plant, making it more vulnerable to attack. However, more N is not always protective, even against facultative pathogens. Some facultative bacterial and fungal foliar diseases proliferate under high N applications because they preferentially feed on young, succulent tissue. N fertilization increases vegetative growth, attracting pathogens with tender new leaves and stems.

Evaluating the crop’s nitrogen status by taking frequent leaf samples and conducting the soil nitrate quick test can help farmers and advisers determine how much N to apply to stay in the proverbial goldilocks zone.

Potassium, Calcium and Magnesium

Potassium (K) fertilizer is another critical defense against crop disease. K applications reduce both facultative and obligate parasite infections through two main mechanisms. First, K can thicken and strengthen cell walls, helping to keep pathogens out. Second, K deficiency impairs protein, starch and cellulose synthesis, leading cells to accumulate amino acids and sugars. Weak cell walls leak these metabolites, attracting and feeding parasitic organisms.

K applications can decrease both disease incidence and severity. Researchers have shown that K fertilization reduces damage from bacterial leaf blight in wheat, rice and cotton. Others have demonstrated reduction in leaf spot, sheath blight and stem rot in a variety of crops (Dordas, 2008).

Calcium (Ca) deficiency promotes pathogen growth in similar ways as K deficiency. Ca is a critical component of cell wall structure and membrane integrity. When Ca levels are low, the plant is vulnerable to fungal infection via the xylem. Once inside the plant, pathogenic fungi damage vascular tissue and the crop wilts.

Ca deficiency can cause severe physiological disorders such as bitter pit in apples and blossom end rot in tomatoes and peppers. Former UC plant pathologist and current director of TriCal Diagnostics Dr. Steven Koike warns against black heart in celery. Black heart, a Ca deficiency disorder, causes young growth in the heart of the plant to brown and blacken. Koike explains that as the celery grows, the necrotic tissue is pushed up and exposed to air where it can easily come into contact with pathogenic fungal spores. Sclerotinia spores aggressively attack damaged tissue leading to severe infection. Ca deficiency in other crops creates similar damaged entry points for pathogens.

Ca fertilizer applications can prevent infection in the field and can continue supporting the yield postharvest. Amending the soil with Ca and increasing pH can suppress clubroot disease in cruciferous vegetables such as broccoli and cabbage. Ca applications can also suppress Pythium, Rhizoctonia and Botrytis. Foliar Ca sprays shortly before or after harvest increase shelf life and help fruit resist rotting (Gupta et al., 2017).

Magnesium (Mg) deficiency is less common and perhaps less obvious than Ca or K deficiency, but Mg is no less important. Magnesium is at the center of chlorophyll and facilitates photosynthesis. When Mg is low, photosynthesis is reduced, causing a cascade of negative consequences. Among other issues, Mg deficiency causes a buildup of sugars and amino acids in leaves, attracting and feeding pathogens. Mg, K and Ca are all positively charged cations and compete for uptake via the roots. Mg deficiency often occurs in high-potassium soils and can be worsened by K fertilization. Pre-plant soil testing can help determine whether Ca, K and Mg fertilization are advisable.

Phosphorous

After N, phosphorus (P) is the second-most widely used mineral nutrient. The effects of P applications on disease suppression are less clear than the other nutrients. P fertilization is most helpful in fighting root rot when applied to seedlings. Plenty of P helps young plants quickly develop strong root systems and escape infection during their most vulnerable early stages of development (Dordas, 2008). P foliar applications can also provide local protection and systemic resistance against powdery mildew in some crops. However, other studies have shown increased disease after P fertilization (Dordas, 2008). Providing adequate P for growth is critical, but applying additional P does not necessarily confer any protection against disease.

Micronutrients

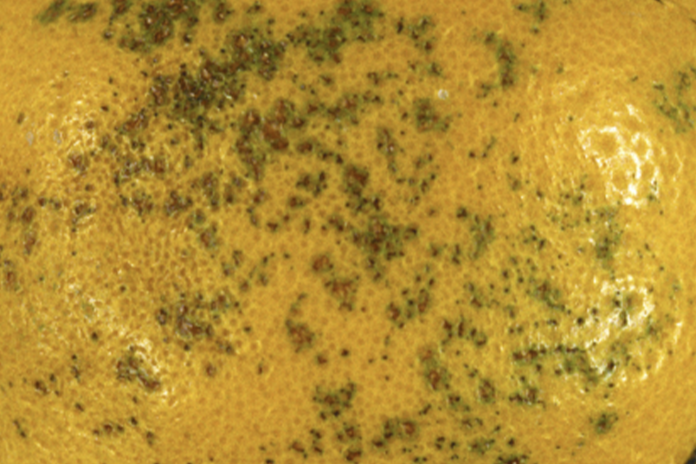

Micronutrients including boron, copper, manganese and zinc affect disease incidence in many ways. Micronutrients are critical to plant metabolism, cellular structure and stress responses. Manganese fertilization can suppress disease by supporting production of lignin and suberin, which provide chemical defense against fungal infection. Low zinc can cause accumulation and leakage of amino acids and sugars as seen with macronutrient deficiencies. Boron is critical to cell structure and lignin formation. Micronutrient applications can also prevent disease by activating the plant’s defense mechanisms against a broad range of pathogens. Deficiencies in any of the micronutrients increases the crop’s vulnerability to infection.

Optimizing Nutrient Management

Complex interactions between the pathogen, the host and the surrounding environment determine disease incidence and severity. We can use nutrient management to strengthen the host and manipulate the soil in ways that suppress pathogens. Whenever possible, determine which diseases your crop will likely face. Review field history and send soil and infected plant tissue to a pathologist like Dr. Steven Koike at TriCal Diagnostics. Conduct preplant soil tests to determine pH and baseline nutrient levels. For example, if you anticipate Fusariam pressure, adjust pH to neutral or slightly alkaline using lime. Plan foliar micronutrient applications to compensate for decreased manganese and iron availability at elevated pH. Other diseases and soil conditions will require different techniques.

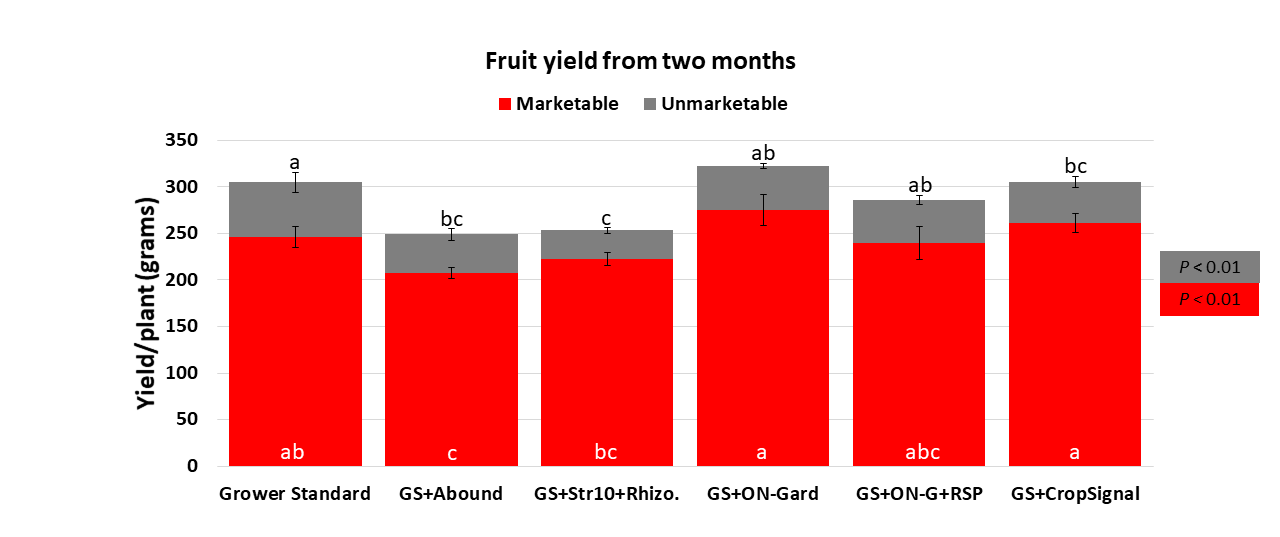

Increasing beneficial microbial activity and increasing soil organic matter can build a suppressive soil environment and simultaneously increase nutrient availability. In addition to nutrient fertilizer applications, consider amending the soil with composts and biostimulant products such as seaweed extracts, humic acids and beneficial microbial inoculants.

Many strategies can increase nutrient availability and help crops defend themselves against disease. The CCA and PCA should develop a plan that will meet the unique conditions on each ranch.

References

Dordas, C. (2008). Role of nutrients in controlling plant diseases in sustainable agriculture. A review. Agronomy for Sustainable Development, Springer Verlag/EDP Sciences/INRA, 2008, 28 (1), pp.33-46. ffhal-00886444f

Gupta, N., Debnath, S., Sharma, S., Sharma, P., Purohit, J. (2017). Role of Nutrients in Controlling the Plant Diseases in Sustainable Agriculture. In: Meena V., Mishra P., Bisht J., Pattanayak A. (eds) Agriculturally Important Microbes for Sustainable Agriculture. Springer, Singapore. https://doi.org/10.1007/978-981-10-5343-6_8.

Huber, D.M. & Haneklaus, S. (2007). Managing nutrition to control plant disease. Haneklaus/Landbauforschung Völkenrode. 4.