Almond shells were applied as a mulch to an established alfalfa field in Yolo County over a two-year period. The intent of the study was to see if alfalfa could serve as a sink for almond shell byproducts after processing without affecting stand productivity. Alfalfa is deep-rooted and fixes nitrogen, which may allow for application of high-carbon materials like almond shell mulches.

The first year, almond shells were applied in October 2021 to a three-year-old stand at 4 to 8 tons per acre. By spring 2022, the almond shells had mostly decomposed. Almond shells were applied to the same test plots in November 2022 at 12.5 tons per acre. Additional field treatments included gypsum at 2 tons per acre per year and an untreated control. In addition to yield, test plots were evaluated for stand vigor, percent cover (bare soil, alfalfa, weeds) and weed pressure. Soil fertility and soil health measurements were also collected during this trial, including aggregate stability, compaction, soil moisture and soil cracking.

Outcomes of Mulch Application on Crop and Soil Metrics

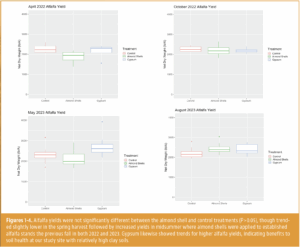

The almond shell mulch did not reduce stand vigor as measured by the number of alfalfa plants per square foot. Alfalfa yields were likewise not significantly reduced (P>0.05), though they trended lower in almond shell plots for the first spring cutting (Fig. 1 and 3) and then evened out and were slightly higher than control plots in late summer for both years of this study (Fig. 2 and 4). Almond shells are high in C and low in N. Amendments with a high C:N ratio can tie up N as they break down. The slight reduction in spring yields might be due to initial spring tie-up of N for feeder roots from the almond shell application.

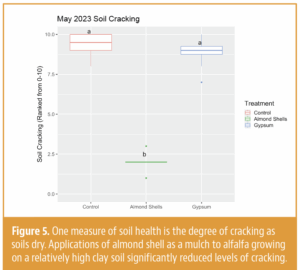

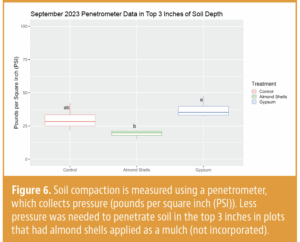

For soil health metrics, almond shell applications showed benefits of reduced soil cracking (Fig. 5) and soil compaction in the top three inches of soil (Fig. 6). Soil cracking is common in clay soils and can tear feeder roots apart in perennial crops like alfalfa. Soil compaction, a common problem in alfalfa due to equipment traffic during multiple harvests, can lead to yield and stand loss, poor water infiltration and reduced microbial activity. Our study shows almond shells provide an opportunity to mitigate surface soil compaction once the alfalfa has established. There were no changes to other soil health metrics like aggregate stability and bulk density after two years of this trial, nor did the almond shell mulch suppress weeds at rates applied.

Apart from electrical conductivity (EC), which measures salinity levels in soil, soil measurements were not significantly different by treatment. Gypsum is a highly soluble salt, and EC was higher in the gypsum plots compared to the almond shell and control plots. Even though differences were not statistically significant, there were some interesting trends in soil measurements. Specifically, almond shells have about 30 pounds of potassium per ton (36 lb K₂O/ton), which can eventually leach into the root zone with rain or irrigation as almond shells decompose. In this project, there was more potassium in soils with almond shell mulch compared to gypsum or control plots. In addition, plots with almond shells had more total carbon and total organic matter. Soil samples were collected in the top foot of soil and shells were applied to the soil surface. It is likely the soil sampling depth affected our ability to measure differences in soil K and C. Other measurements like cation exchange capacity, magnesium, calcium and total N were not different by treatment.

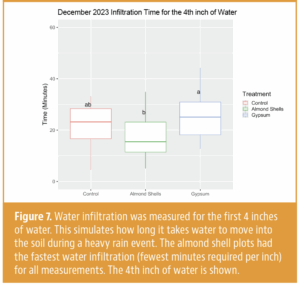

Soil water measurements were collected in this trial. Infiltration measurements were taken for the first four inches of water applied. Infiltration measures the rate at which water moves into the soil. Infiltration was fastest in plots with almond shells for all 4 inches of water. However, the differences were only statistically significant for the 4th inch of water (Fig. 7). In a heavy rain event, rapidly moving water into the soil is advantageous for preventing runoff and retaining water in the fields. Saturated hydraulic conductivity measures the rate that water flows through saturated soil. Though not statistically significant, almond shell plots also had a faster saturated hydraulic conductivity (faster water flow rate) compared to other treatments.

Volumetric water content was measured in the top 6 inches of soil. The total differences in soil water content at any point in the season were negligible for on-farm irrigation decisions. However, some interesting trends were observed. In rainy months, almond shell plots had higher water content after rain events, likely because of increased infiltration and hydraulic conductivity. However, in the summer months, almond shell plots had slightly less water in the top 6 inches of soil. These are the months when the yields trended slightly higher in the almond shell plots. Alfalfa is a crop that yields relative to water applied; this reduction in water content is likely due to the increased alfalfa yield in plots with almond shell application.

Cost Considerations and Logistical Factors of Shell Application

Almond shells are both bulky and very lightweight, making them challenging to spread compared to other amendments. However, shells are a dry material, and transportation costs are not lost to water weight as with other soil amendments like compost. Good soil coverage requires a high volume of shells per acre, and multiple truckloads per field will be needed. This increases hauling and spreading costs. For the Sacramento Valley where this field trial was conducted, freight costs are $10 per ton within 50 miles and spreading costs are $15 per ton. These costs are high given the lack of measurable differences to soil fertility and yield. Thus, this practice is best suited for established alfalfa fields located near a source of almond shells to reduce freight costs.

Mulching is considered a soil conservation practice under both federal and state guidelines. However, mulch must be applied to a 2-inch depth and at a rate to achieve 70% soil coverage. At the highest application rate in our study (12.5 tons/acre), the depth of the mulch was under 1 inch.

Key Takeaways

In our study, almond shell mulch in an established alfalfa field showed benefits of reduced soil cracking, reduced soil compaction and increased water infiltration without negatively affecting overall stand health and yields at the rates of almond shells applied. Alfalfa has deep roots and fixes N, making it a resilient crop for diverting high-C almond shell waste byproducts from nearby orchards to alfalfa stands, improving organic matter recycling in the region. Since almond shells are not incorporated, any N tie-up would be slow and only in the soil surface. Incorporating almond shells to alfalfa stands prior to planting or applying shells to first-year stands is not recommended due to issues with tying up N with a high C:N product that could affect stand establishment and plant growth. This project was an initial evaluation and did not quantify the optimum application rate to alfalfa fields.

Funding was provided by the California Alfalfa and Forage Research Foundation. Thank you to our grower collaborator for supporting this work.

The original version of this article first appeared in the April/May 2025 issue of Hay & Forage Grower.