Listen to the audio version of this article (generated by A.I.)

Mechanized pruning in grape production aims to improve productivity by means of uniformity, timeliness and cost effectiveness. It also helps to address the farm labor shortage situation facing the grape industry. The difference in the outcomes of manual and mechanized pruning from the viewpoint of pesticide spray application to grapevines is minimal to nonexistent. Figure 1 shows examples of manually pruned versus mechanically pruned grapevines, indicating similarity in appearance. In both cases, the vine canopies undergo the same temporal changes, from non-foliated canopies at the beginning of the production season to fully foliated canopies later in the season.

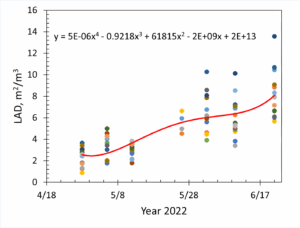

As the number of leaves increase inside the canopy, the leaf area density (LAD) also increases. LAD, with units of square meters per cubic meter, is defined as the total leaf area (m2) per unit volume of canopy (m3). LAD represents the available leaf area in the target canopy that applied spray should deposit on. Figure 2 shows an example of the temporal variation of LAD in canopies of a of manually pruned grape over part of the season. Increasing LAD trends figure are attributed to rapid increase in canopy foliage as leaves form while decreasing LAD trends can be attributed to spreading out of the canopy due to limb elongation during the vegetative stage or gravitational effect as leaves and fruits weigh down on branches.

Hence, when considering spray technology needs or practice beyond pruning, there is virtually no difference between a manually pruned and a mechanically pruned vineyard. The same principles and best practices apply. In the San Joaquin Valley, about 76% of vineyard pesticide applications are done using conventional airblast sprayers, based on 2023 data. The remainder is done using tower sprayers (10%), electrostatics mist blowers (7%) and other sprayers (7%).

Basics of Spray Application

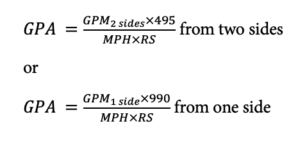

During spray application using any of the aforementioned sprayers, the sprayer travels between vine rows applying spray on both sides. Basically, the immediate vine canopies adjacent to the sprayer are considered the target canopies, and both sides of the canopy need to be sprayed to achieve full coverage. Standard sprayer calibration calculations view only half of the vine row per side as being sprayed at any given time. Therefore, it is sufficient and most efficient for the sprayer air to carry the spray to the target canopy with only enough penetration, as excessive penetration could reduce the level of spray deposition and increase drift potential. The volume of spray applied is calibrated as follows:

where GPA is gallons applied per acre, GPM2 sides and GPM1 side are the total flowrates (in gallons per minute) from all open nozzles, MPH is the calibrated forward speed (miles per hour) of the sprayer, and RS is the vine row spacing (feet).

Some other commercial sprayers are designed to treat multiple vine rows in a single pass. In such cases, the calibration formulas provided above should be revised accordingly to accurately calculate GPA. To do this, RS would need to be multiplied by the applicable values of 2, 4 or 6.

Considerations for Efficient and Effective Spray Application

Three components are important for achieving an efficient and effective application: the sprayer (equipment), the spray (material) and the operator or spray crew. The sprayer must be well-maintained to provide the intended functionality, well-calibrated to achieve accurate GPA in accordance with the pesticide label and well-adjusted to target canopy characteristics. This means the number of open nozzles should not result in too much spray applied over and/or under the canopy. In the actual application, the sprayer needs to be well-operated, maintaining the calibrated settings.

For effective pest control, the spray application must be properly timed both in terms of the target pest and the weather conditions at the selected time of application. The spray must also be accurately applied to achieve the intended dosage to control the target pest. To maximize this dosage, the spray should be well-directed to the target canopy. The pesticide mix should be optimized for both coverage and on-target deposition to prevent excessive runoff of spray liquid from leaves. The level of air assistance from the sprayer should be appropriate for adequate penetration. The need for air assistance in vine and tree spray applications is well established and cannot be overstated. However, research studies demonstrate using too much air assistance can result in reduced on-target deposition and increased drift potential due to overpenetration.

Furthermore, the success of an application depends on the skill and knowledge of the operator or spray crew. They should be familiar with spray application best practices and be willing to adhere to them. They should be attentive to sudden changes in the field (e.g., an abrupt change in wind speed and/or direction toward a sensitive site) and be able to delay or postpone applications until a more suitable time.

Whether applying spray to a manual or mechanized pruning vineyard system, effectiveness is not just about achieving the desired GPA. More than that, it is about getting adequate spray material to the target so the desired levels of spray coverage, on-target deposition and pest control can be achieved. Afterall, spray that deposits on the target is the spray at work.