Listen to the audio version of this article (generated by A.I.)

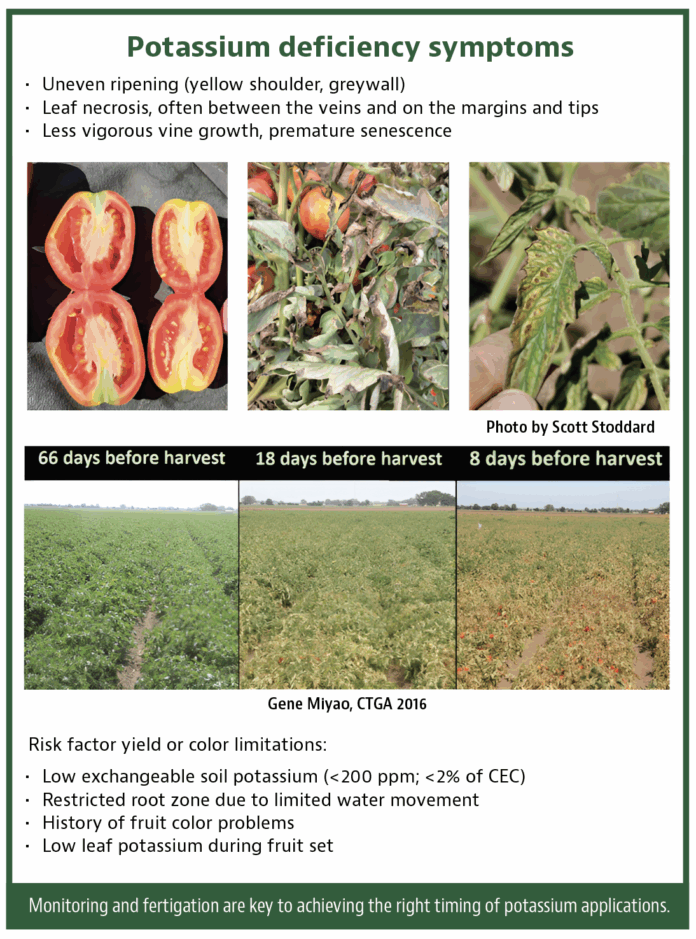

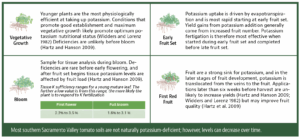

Potassium is important to tomato vine health, fruit set and color. Recognizing where deficiencies may occur and correcting them is complex.

Deciding if Potassium Fertilization is Necessary

The K ion is weathered from soil minerals and is held on negatively charged soil surfaces (the cation exchange capacity, or CEC). The plant’s ability to get the K it needs depends therefore on:

• Soil type and texture: Sandy soils have a low CEC and a limited capacity to supply and hold K, while heavy clay soils can limit water movement and root growth, meaning that while the soil may have sufficient K the tomato roots cannot access it.

• Root growth: Since K isn’t very mobile in most soils, plants with poor root systems will have less access to soil K, even if it’s in an available form.

• Presence of other cations: If other ions are too abundant, they interfere with the plant’s ability to take up soil K. If K makes up less than 2% of the soil’s CEC, plants risk being K-deficient.

Right Rate

Tomatoes are heavy K feeders, and most of the K taken up goes to the fruit. A 50-ton crop can remove 200 to 300 pounds K per acre (4 to 6 pounds per ton; Hartz and Hanson 2009). If K fertilization is needed, a recommendation is to replace the K removed with the harvest. The economic rate may be less than this because the additional yield benefit often stagnates as the rate increases (Hartz and Hanson 2009). A general recommendation is 100 pounds K2O per acre (Hartz and Hanson 2009).

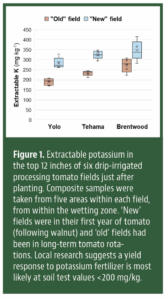

Most southern Sacramento Valley tomato soils are not naturally K-deficient; however, levels can decrease over time. In an ongoing project funded by CTRI, I am measuring soil biological, chemical and physical differences between fields which are coming into tomato for the first time in decades (e.g., after walnut) and nearby fields on the same soil type which have been in long-term tomato rotations. Across a range of soil textures (Yolo silt loam, Tehama loam and Brentwood clay loam), all ‘new’ fields contained more available K in the top 12 inches at planting than their ‘old’ counterparts (Fig. 1). The difference was greatest on the two lighter soils. These differences may not relate to crop yield as only one field is at the threshold at which drip-irrigated processing tomatoes are expected to respond to K fertilizer, but they suggest that even in high-K soils, annual rotations which include tomato measurably reduce K over time.

Questions about nutrient management in processing tomatoes? See the California Fertilization Guidelines at geisseler.ucdavis.edu/Guidelines/Tomato.html.

References

Hartz, T.K., Hanson, B., 2009. Drip irrigation and fertigation management of processing tomato . University of California Vegetable Research and Information Center.

Hartz, T.K., Johnstone, P.R., Francis, D.M., Miyao, E.M., 2005. Processing tomato yield and fruit quality improved with potassium fertigation. HortScience 40 (6): 1862-1867.

Widders, I.E., Lorenz, O.A., 1982. Potassium nutrition during tomato plant development. Journal of the American Society of Horticultural Sciences 107 (6): 960-964.