Increasing demand for organic produce and lack of herbicides for this crop sector has resulted in high weeding costs for many vegetable crops. Organic fields tend to be weedier than conventional fields because organic crops have fewer weed control tools. Lack of residual herbicides for organic crops means a missed cultivation or hand weeding pass often results in weeds escaping and producing weed seed, making the problem worse. Most conventional crops have residual herbicides that provide some protection against weed escapes, such as during wet conditions when it is not possible to cultivate or hand weed. Organic crops lack the protection residual herbicides provide.

Increasing labor costs and labor shortages mean hand weeding costs continue to climb, and laborers may not be available when needed. Loss of Dacthal has eliminated a key weed control tool for vegetables, and new options are needed. It is unlikely new herbicides will replace old products like Dacthal that are lost to small markets like vegetable crops. More recent technologies, such as the new intra-row intelligent cultivators and laser weeders, help reduce the number of weeds that must be removed by hand, but they do not eliminate the need for hand weeding.

Few methods are available for organic crops to achieve residual control of weeds. Possible methods are soil solarization and steam. Both methods kill weed seed in the shallow seedbank using thermal heat to kill weeds. Here, we will discuss the use of steam for residual weed control.

How Does Steam Work?

Water heated above 212 degrees F becomes steam. Steam injected into soil transfers the heat from the steam to the soil particles, heating them and killing nearby pathogens and weed seed. Steam condenses onto the cooler soil particles, releasing its heat as it returns to the water phase. Once vaporized, steam can be heated to higher temperatures, becoming “dry steam.” The advantage of dry steam is it disperses further into the soil, transferring the heat energy to a larger volume of soil than would be the case with a cooler “saturated steam,” which holds a lot of water droplets. Target temperatures of the soil will range between 150 degrees F to 180 degrees F. The objective is pasteurization, not sterilization. Maintaining temperatures in this moderate “Goldilocks” range will control most pathogens and weed seed while not damaging beneficial soil microbes.

Benefits of Steam

Steam injected into soils controls both weed seed and soilborne pathogens. Guerra et al. (2022) found field steaming reduced weed emergence and subsequently improved hand weeding efficiency. The residual effect of steam on weeds is because it kills weed seed in the steam-treated zone, thus reducing weed emergence. Furthermore, Guerra et al. (2022) found steam controls pathogens, such as Pythium spp. and Sclerotinia minor. Additionally, Lu et al. (2009) reported a 90% reduction in Fusarium oxysporum with steam treatments at 158 degrees F or higher. In regions like Monterey County, where Fusarium oxysporum f. sp. lactucae severely affects lettuce production and Pythium ultimum threatens leafy greens, addressing these diseases is critical (Martin and Loper 1999).

Interest in sustainable practices like steam disinfestation has grown due to rising labor costs and regulatory pressures on fumigants. Originating in the 1880s, steam disinfestation effectively controls weeds and eliminates soilborne pathogens (Baker 1962). The earliest approach, broadcast sheet steaming, involved applying steam to the entire soil profile, but this method consumed excessive energy and had limited efficiency (Gay et al. 2010a). Band steaming, which injects steam into narrow seedline bands prior to seeding, offers higher efficacy with reduced resource input (Guerra et al. 2022) (Fig. 1). This method effectively addresses persistent weed and pathogen control issues (Guerra et al. 2022; Gullino 2022; Fennimore et al. 2014). The thermal energy kills weed seeds and pathogen propagules at soil temperatures above 70 degrees C (Baker 1962).

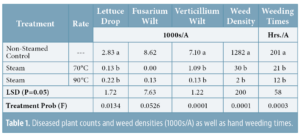

Band steaming effectively reduces soilborne pathogens such as Pythium spp. and Fusarium spp. (Guerra et al. 2022; Kim 2021; Fennimore 2014). Due to their significant environmental and health impacts, chemical controls for soilborne diseases, such as methyl bromide, were phased out in 2005 (Fennimore et al. 2008). In the Salinas Valley, Fusarium spp. and Pythium spp. are prevalent, affecting key crops like strawberries and lettuce. Recent studies with steam in the Salinas Valley found steam reduced incidence of lettuce drop, fusarium wilt, verticillium wilt and weeds in lettuce (Table 1; Fennimore unpublished).

Where Does It Fit and How Much Does It Cost?

Steam is most appropriate for high-value vegetable crops, such as organic carrots, lettuce and spinach, where weed control costs are high. High-density crops, such as carrots, spinach and spring mix lettuce, are grown at high densities, making it difficult to cultivate or hand weed. It may be possible to precisely apply steam to these crops at a cost that is less than the cost of labor. That is the objective of our work with steam. Weed seed in the soil killed by steam do not emerge, and therefore steam is a prophylactic treatment in advance of the pest. This contrasts with intelligent cultivators and laser weeders, which control weeds after they emerge. It is possible that preplant steam application followed by intelligent weeding technologies could remove the need for hand weeding completely.

We have often observed more than a 90% reduction in hand weeding of steam treated plots compared to a no steam treated plots. For Pythium spp. where steam is applied 6 inches deep, this pathogen is reduced by 99%. Similar results have been obtained for Verticillium wilt and lettuce drop. Fusarium is more difficult to control, and higher temperatures (190 degrees F) are needed to control this pest.

We tested a custom-built steam applicator for vegetable crops in 2024 (Fig. 2). The machine injects dry steam into bands aligned with where the crop will be seeded in a subsequent operation.

We are currently working with partners to commercialize this process. Reductions in hand weeding of 90% (Table 1) could reduce hand weeding costs by $200 per acre. The reductions in Fusarium infection could mean the difference between a net income of $4,550 with no steam compared to a net income of $17,500 in iceberg lettuce, meaning the value of steam treatment could be worth $12,950 per acre.

Beneficials

Our findings suggest although band steaming initially disrupts the soil microbiome, significant recovery occurs within 30 days, supporting its potential to preserve long-term soil health while suppressing soil pests. The novelty of band steaming lies in its precision, targeting soils only where needed in the seedline where crops will be planted. This focused approach minimizes the overall impact on the soil, allowing unaffected areas to support microbiome recovery. This research reinforces the viability of band steaming as a sustainable and environmentally friendly alternative for pest control in agriculture, while maintaining soil biodiversity and functionality.

Band steaming for field grown vegetable crops provides a much-needed new tool for weed and pathogen control for vegetable crops. The process controls several key diseases and weeds, without damage to soil health. Work is currently underway to commercialize band steaming and to reduce cost of application.

References

Baker, K.F. 1962. Principles of heat treatment of soils and planting material. J. Aust. Inst. Agric. Sci. 28:118-126.

Fennimore, S.A., F.N. Martin, T.C. Miller, J.C. Broome, N. Dorn, and I. Greene. 2014. Evaluation of a mobile steam applicator for soil disinfestation in California strawberry. HortScience 49(12):1542-1549. https://doi.org/10.21273/HORTSCI.49.12.1542.

Gay, P., P. Piccarolo, D. Ricauda Aimonino, and C. Tortia. 2010a. A high efficiency steam soil disinfestation system, part I: Physical background and steam supply optimization. Biosystems Eng. 107:74-85.

Gay, P., P. Piccarolo, D. Ricauda Aimonino, and C. Tortia. 2010b. A high efficacy steam soil disinfestation system, part II: Design and testing. Biosystems Eng. 107:194-201

Guerra, N., S.A. Fennimore, M.C. Siemens, and R.E. Goodhue. 2022. Band steaming for weed and disease control in leafy greens and carrots. HortScience 57:1453-1459. https://doi.org/10.21273/HORTSCI16728-22.

Kim, D.S., S. Kim, and S.A. Fennimore. 2021. Evaluation of broadcast steam application with mustard seed meal in fruiting strawberry. HortScience 56:500-505. https://doi.org/10.21273/HORTSCI15669-20.

Martin, F.N., and J.E. Loper. 1999. Soilborne plant diseases caused by Pythium spp.: Ecology, epidemiology, and prospects for biological control. Crit. Rev. Plant Sci. 18:111-181. https://doi.org/10.1080/07352689991309216.

Lu, P., D. Ricauda Aimonino, G. Gilardi, M.L. Gullino, and A. Garibaldi. 2010. Efficacy of different steam distribution systems against five soilborne pathogens under controlled laboratory conditions. Phytoparasitica 38(2):175-189. https://doi.org/10.1007/s12600-010-0086-8.