The use of pesticides can be very effective in protecting trees from pests and diseases. However, many times this is also accompanied by negative impacts on humans and the environment. Off-target movement of chemical spray has always been a challenge for growers because it can contaminate the environment, reduce spray efficacy and impose liabilities.

California has stringent pesticide laws and regulations and orchard spray application is considered a high-risk operation. California law establishes a buffer between schools and any pesticide spraying location. Growers are required to notify the public when they spray pesticides. This includes schools, daycare facilities, and county agricultural commissions.

Spray drift can be reduced by choosing the right type of nozzle, adjusting and calibrating sprayer settings, defining shelter zones and specifically modified practices in the downwind rows. Reducing the movement of spray droplets to sensitive areas might be accomplished by these methods, but they are in clear contrast with strategies that lead to a uniform on-target deposition. For instance, spraying with larger droplets can reduce the amount of drift, but it also decreases the effectiveness of the spray at higher parts of a tree. Likewise, reducing airflow results in reduced drift; however, it also diminishes the spray efficacy in zones farther from the sprayer, for example, on treetops. Drift can also be reduced when we use slower ground speed and higher liquid flow rate, but the impact is not significant.

Spray Backstop

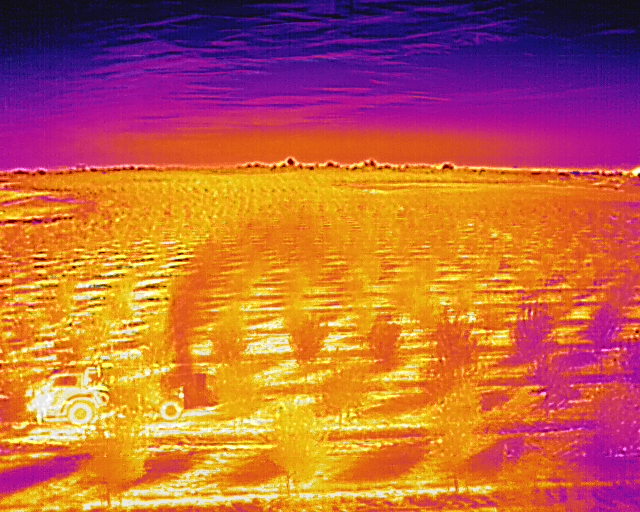

At the Digital Agriculture Lab at UC Davis, a sprayer attachment system called Spray Backstop was developed to minimize drift potential and possibly improve spray coverage on the treetops. The backstop system is a screen structure that can be raised above the trees using a foldable mast.

A test was conducted in a mature almond orchard to determine how much drifting could be reduced with the backstop system. A cotton ribbon loop was stretched around the trees to quantify the droplets scaping the tree canopy. The ribbon could capture all spray droplets that did not deposit on-target and were not blocked by the backstop system.

The orchard was sprayed with a mix of water and fluorescent dye. The ribbon was cut into sub-samples and analyzed with the fluorometry method. Comparing the ribbon samples from the test with and without the backstop showed that the Spray Backstop system could effectively block the spray droplets escaping the canopy from treetops or sides and reduce drift potential by 78%. Leaf samples were also collected from trees in both spray application conditions and analyzed by the fluorometry technique. Unlike the conventional drift control methods, using the spray backstop system does not change overall canopy deposition and could also help improve deposition on treetops.

Adopting the spray backstop system into the orchard spray application practice will reduce the environmental degradation while protecting residential areas and schools from exposure to chemicals. On the other side, growers can adjust their sprayer for more air and finer droplets (that will improve spray coverage and efficacy in the upper canopy area) without being concerned about drifting because the backstop system can stop spray droplet movement above the trees. A uniformly applied treatment will significantly reduce the risk of crop failure due to pests and diseases.

The spray backstop system is simple and could be easily implemented without significant modifications to the grower’s spray rigs. This system can help growers to be compliant with pesticide regulations and maintain good environmental stewardship. You can find more information about the spray backstop project at the digital Agriculture lab website: digitalaglab.ucdavis.edu.